Updated: January 23, 2026

Written by Dan Simms

Laura Madrigal is the Home Design Specialist at Fixr.com, dedicated to identifying and analyzing significant changes within residential design. She is the author of leading trends reports on interior design, kitchen, and bathroom, and her insights have been featured in publications like Realtor and the New York Post.

Learn moreReviewed by Laura Madrigal

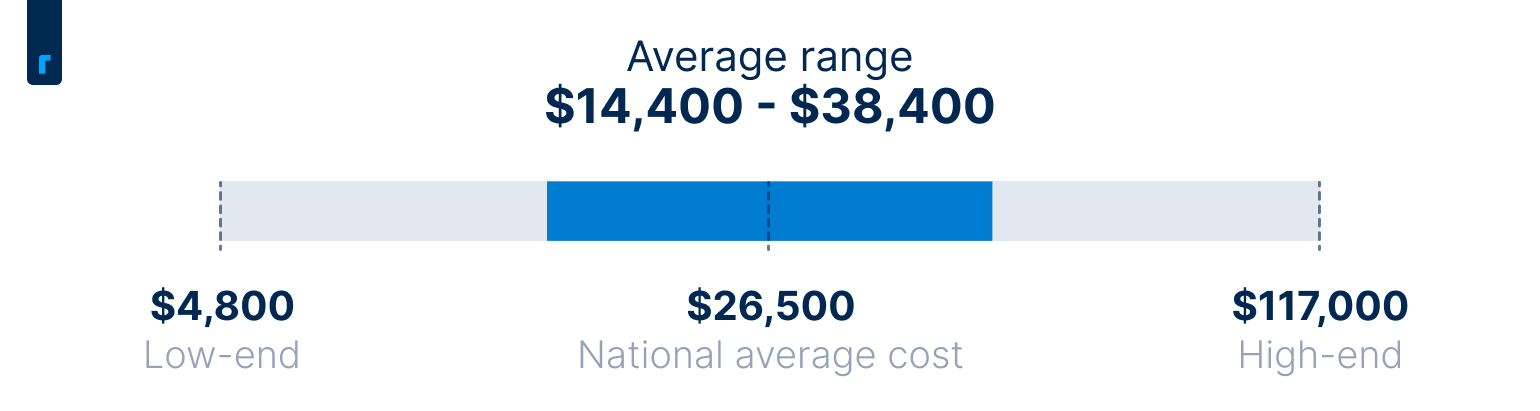

The average cost to install a 2,400 sq.ft. steel roof is $26,500, with most homeowners paying between $14,400 and $38,400. Total cost depends on roof size, metal type, roof style, pitch, and overall complexity.

Metal roofing is a durable alternative to asphalt shingles, offering a longer lifespan, low maintenance, and strong performance in most climates. Metal roofs resist impact, handle high winds well, shed snow efficiently, and reflect heat to improve energy efficiency in warmer regions. They are also recyclable, making them a more sustainable roofing option.

Cost of Metal Roof

Metal Roof Cost per Square Foot

Metal roof installation costs an average of $11 per square foot, including materials and labor. Prices typically range from $3 to $30 per square foot, depending on the metal and roof profile.

Roofing square footage is higher than interior square footage due to slope and overhangs. For example, a 1,000-square-foot home needs an average of 1,200 square feet of roofing, and a 2,000-square-foot home needs 2,400 to 2,500 square feet of roofing.

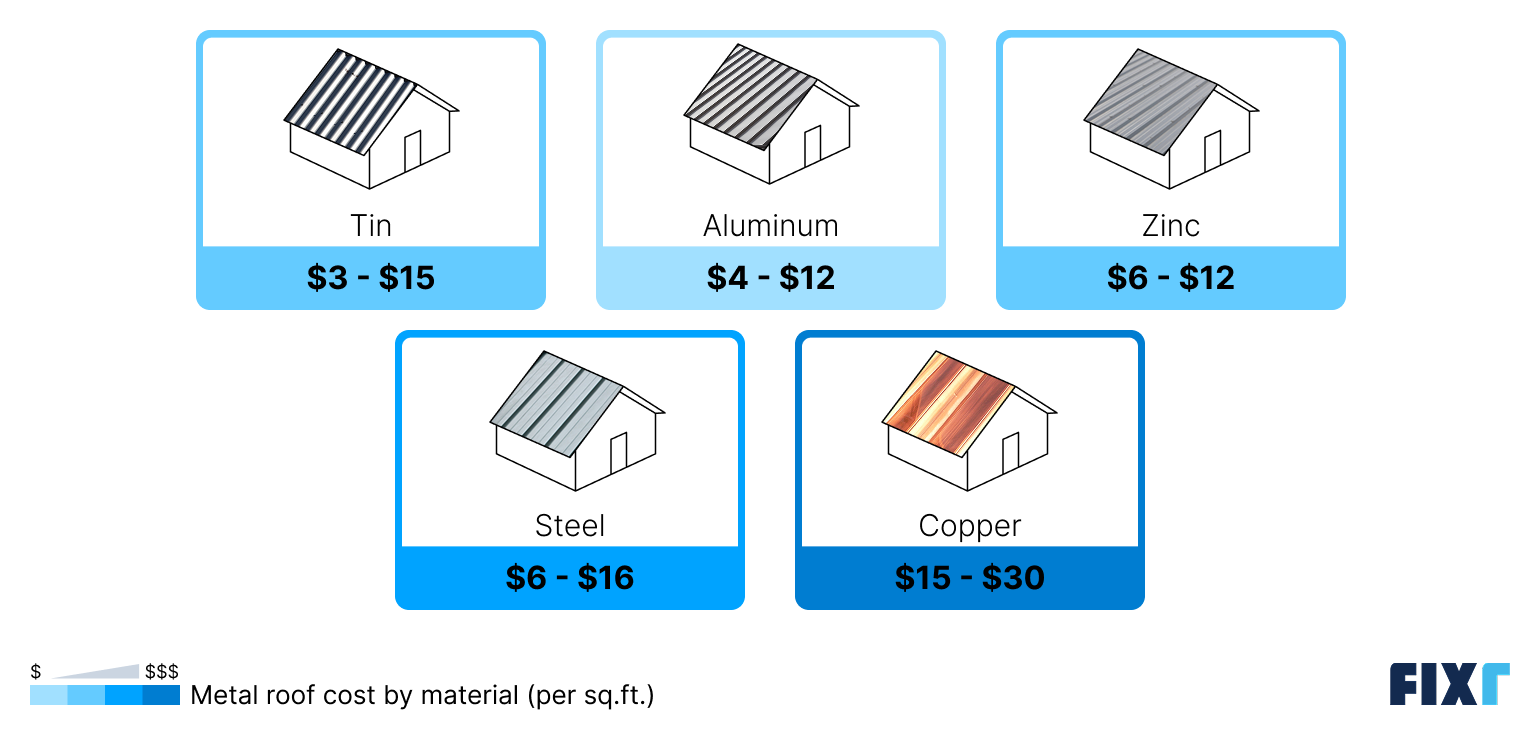

Metal Roofing Cost by Material

The type of metal you choose for your new roof will have a major impact on your total costs. Prices below include materials and installation.

Material | Cost per Sq.Ft. |

$3 – $15 | |

$4 – $12 | |

Zinc | $6 – $12 |

Steel | $6 – $16 |

$15 – $30 |

Tin

Tin is the most affordable option at $3 to $15 per sq.ft. It can last up to 70 years, but it is softer than other metals, making it more prone to denting and fastener movement. You can choose to paint or powder coat your tin roof for added protection.

Aluminum

Aluminum roof costs between $4 and $12 per square foot. Aluminum resists rust, making it ideal for coastal areas, but it also dents more easily than harder metals like steel. In general, it offers good value with minimal maintenance.

Zinc

Zinc roofing costs between $6 and $12 per square foot. Zinc can outlast many other roofing materials, potentially lasting up to 100 years. It develops a beautiful patina, like copper, and makes for a unique home appearance. Zinc resists corrosion but dents more easily due to its softness.

Steel Roof Cost

Steel roofing costs between $6 and $16 per square foot. It’s the most common metal roof due to its strength, long lifespan (up to 60 years), and balanced cost. However, protective coatings are required since steel is prone to rusting.

Copper

Copper roofs cost $15 to $30 per sq.ft. and are considered a premium option. They develop a distinctive patina and can last 100 or 200 years, but they require a higher upfront investment. The material is relatively soft, too, so you may need ongoing maintenance and dent repair if you live in a more extreme climate.

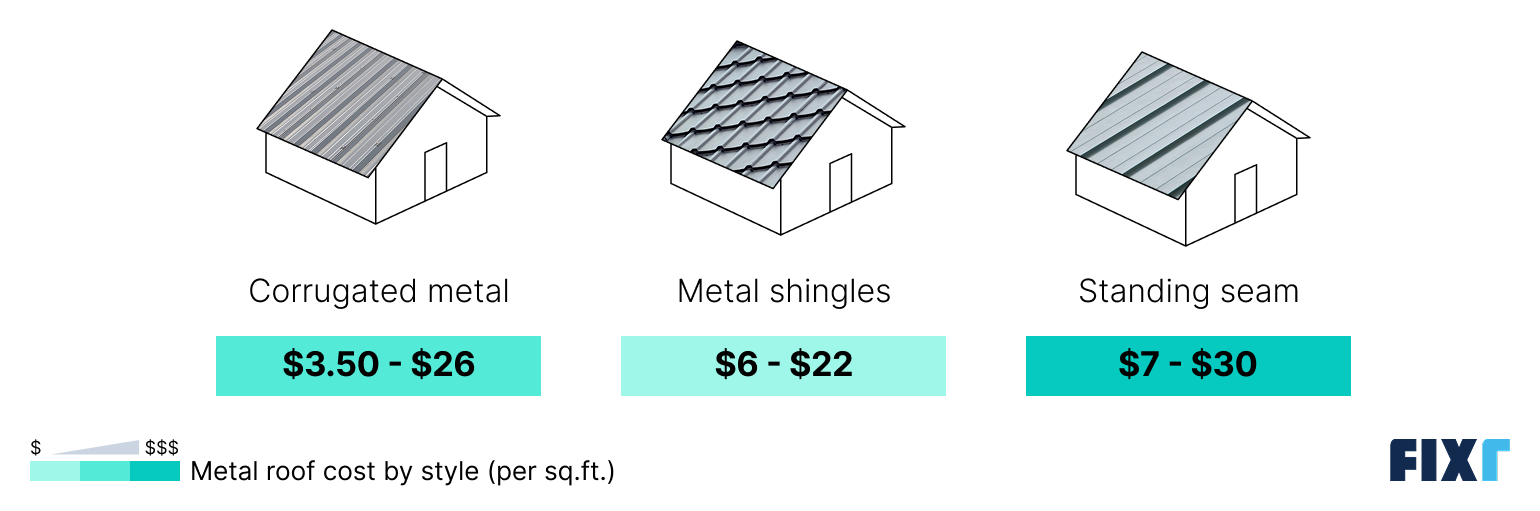

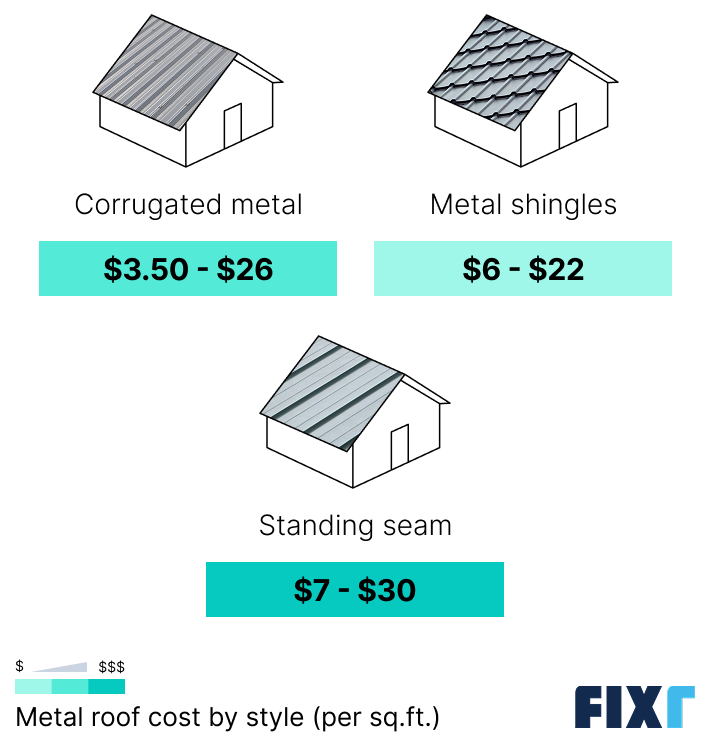

Metal Roof Cost by Style

In addition to the type of metal, you have some options for the style of metal roof you install.

Standing seam roofs are the most popular and durable, with hidden fasteners that reduce leaks and wind uplift.

Corrugated metal is the least expensive but is usually reserved for sheds and garages due to exposed fasteners and appearance.

Metal shingles offer a balance of cost and curb appeal but are more labor-intensive to install.

Type | Cost per Sq.Ft. |

Corrugated metal | $3.50 – $26 |

Metal shingles | $6 – $22 |

Standing seam | $7 – $30 |

Metal Roof Replacement Cost by House Size

Like all roof materials, your roofer will price out your metal roof installation based largely on the square feet of roofing you need, and both materials and labor will scale with roof square footage. Larger roofs require more materials and will take longer to cover. Roofers may loosely charge based on a specific cost per square foot, but since roofs vary so widely in design and complexity, you’ll more likely get just a total for your roofing project rather than a breakdown by size.

You can get the most accurate estimate if you know how many square feet of roofing you need to cover your home. However, more homeowners know their home’s square footage, and while these measurements differ, they are correlated. You can use the table below to get an idea of the average metal roof installation cost based on home size.

House Size (Sq.Ft.) | Cost Range |

1,000 | $4,800 – $36,000 |

1,500 | $7,200 – $54,000 |

2,000 | $9,800 – $73,500 |

2,500 | $12,200 – $91,500 |

3,000 | $15,600 – $117,000 |

Labor Cost to Install Metal Roof

The average labor cost to install a metal roof is between $3 and $12 per square foot or between $300 and $1,200 per square. Labor typically accounts for between 50% and 80% of your total.

Labor costs vary significantly due to material costs for different metal types, installation complexity from diverse roof shapes, and designs.

Additional Factors Affecting the Cost of Metal Roofing

The type of metal roof you choose and the style are the two biggest cost factors you need to consider, but there are a handful of other additional costs to consider if you want the most accurate estimate possible.

Gauge of Metal

Unlike most other roofing materials, metal roofs come in varying thicknesses. Metal roofs for residential use are usually available in gauges ranging from 22 gauge to 29 gauge, with lower gauge numbers representing thicker, more durable, and more expensive products.

Coating or Paint

Unless you’re installing copper or zinc roofing for the natural patina, you’ll most likely want your metal roof powder-coated or painted. Painted or powder-coated finishes improve appearance and protect against corrosion. Investing in higher-quality coatings costs more, but it’s usually worthwhile, especially on steel roofs.

Roof Pitch and Complexity

Steeper roofs and complex designs require more material, safety equipment, and labor. Roof features like valleys, hips, and dormers increase flashing and overall installation time.

Existing Roof Removal

While it’s possible to install a metal roof over existing shingles, it’s usually best to rip the old roof off and start fresh. Removing an old roof costs between $1,000 and $7,400, depending on the size and the weight of the old materials. Slate and clay roofs can push toward the higher end of that range, while removing an asphalt shingle roof is the cheapest.

Underlayment

There are different underlayment options for metal roofing that range from $0.05 up to around $0.50 per square foot, including materials and labor. Ask your roofing contractor which type of underlayment is right for your climate.

Is Metal Roofing Worth It?

Metal roof installation costs two to three times as much as an asphalt shingle roof, so upfront cost and long-term value are crucial factors to consider when considering a metal roof. While they are more expensive, they last at least twice as long as asphalt shingles.

Metal roofing requires less maintenance, resists leaks and wind damage, and can reduce cooling costs. This translates into long-term value that is often equal to or better than asphalt roofing.

Metal vs. Asphalt Roof Cost

Metal roofs average $11 per square foot to install, while asphalt shingle roofs average $4 per square foot. Metal roofs are significantly more expensive, but they require virtually no maintenance and provide better protection from potentially expensive roof leaks. Many homeowners also prefer the look of metal roofing, although the ROI for asphalt shingle roofs tends to be higher due to lower installation costs.

DIY vs. Professional Installation

With an average of between 50% and 60% of your total metal roof installation costs going toward labor, DIYing often seems like a good option. However, it’s most definitely not worth it in the long run.

Metal roofs are heavy, slippery, and require precise installation. DIY installation will void most manufacturers’ warranties and may not be covered by insurance. Professional installation provides better safety, appearance, and long-term value.

Ways to Save Money on a Metal Roof

Metal roofing can get expensive, but luckily, there are several steps you can take to reduce costs.

Choose your materials carefully: Choose a highly durable material that can stand up to severe weather and offers good longevity for value. Steel is one of the best options overall for balancing cost and value.

Pick a less expensive style: Steer clear of corrugated metal roofing if you want a good return on investment and curb appeal, but consider metal shingles over a standing seam metal roof to save some money.

Aim to get the work done during the off-season: Roofers are busiest during the late spring and early summer, so waiting until the fall to replace your roof could mean lower labor costs.

Look for tax credits and rebates: Metal roofing may qualify you for energy efficiency rebates, tax credits, and other incentives, especially if you choose a light colored metal roof, which is considered a “cool roof.” Check the Database of State Incentives for Renewables and Efficiency (DSIRE) for incentives in your area.

Get at least three estimates: Shop around and get at least three estimates for your metal roof installation. Be sure to ask each contractor for a quote for the same metal, roof thickness, and style, and compare them side-by-side to find the best value.

Understand when you can call on insurance: If your old roof was damaged beyond repair from extreme weather, you may be able to get the cost of a new metal roof partially covered if you open a homeowner’s insurance claim. You’ll need to pay a deductible, but this could mean significantly less money out of your pocket.

FAQs

The average cost to install a metal roof on a 2,000-square-foot house is $26,950, but your total could range from $9,800 to $73,500, depending on the specific materials you choose.

A metal roof can cost anywhere from $3 to $30 per square foot to install, and the average cost of a metal roof is around $11 per square foot. The actual cost will depend on the type of metal, the style of roof, and the roof gauge.

Metal roofs have two main downsides: their high upfront cost and potential noise. They can be two to three times pricier than asphalt shingles, though they last longer. Additionally, heavy rain can make them noisy, requiring insulation beneath the metal to reduce sound.

Metal roofs last an average of 50 to 70 years, so you should expect to have to replace them every 60 years or so. However, the lifespan depends on many factors, including the climate in your area and the type of metal you choose.