Updated: January 31, 2025

Written by Adam Graham

Cristina is a home remodeling and design specialist with more than 5 years of experience in the industry. As a former member of the Fixr.com editorial team, she collaborated with industry experts to deliver accurate and reliable information on trends, news, and advice for homeowners and professionals. Her work has been featured in major publications including Forbes, Realtor.com, and the official publication of the National Kitchen & Bathroom Association.

Learn moreReviewed by Cristina Miguelez

People with physical handicaps and mobility challenges often have difficulties navigating their way around the home. Considering 13.7% of adults with disabilities in the U.S. have mobility issues, safe mobility solutions are a priority. Wheelchair ramps are among the most common examples. Many homeowners choose to install ramps both indoors and outdoors. Suppose you or a family member requires a wheelchair ramp for better mobility and comfort at home.

The national average cost for installing a ramp is $1,700 to $5,000. Most people pay around $3,000 to install a 10-foot modular aluminum ramp. At the low end of the spectrum, you can opt for a portable rubber doorway ramp for $50. At the high end, you can pay up to $8,000 to install a permanent L-shaped concrete ramp with railings.

Wheelchair Ramp Installation Price

| Wheelchair Ramp Installation Cost | |

| National average cost | $3,000 |

| Average range | $1,700-$5,000 |

| Low-end | $50 |

| High-end | $8,000 |

Wheelchair Ramp Cost per Foot

Project costs for installing a new ramp for a safer home are often priced per foot. These prices for a quality low-slope design can vary based on the chosen material. However, costs generally range between $50 and $250 per linear foot for the material only. Ramp measurements vary greatly depending on the location and the main use of the ramp. For example, a 4 ft. or 8 ft. ramp would most likely be used for a short doorway or several steps, while a 20 ft ramp is more common for front porch or driveway ramps. Because the installation price depends on the material, location, and ramp slope, the table below shows the average material cost for the common wheelchair ramp sizes.

| Size | Ramp Cost (Materials Only) |

| 4 Feet | $200 - $1,000 |

| 8 Feet | $400 - $2,000 |

| 10 Feet | $500 - $2,500 |

| 12 Feet | $600 - $3,000 |

| 15 Feet | $750 - $3,750 |

| 16 Feet | $800 - $4,000 |

| 20 Feet | $1,000 - $5,000 |

Wheelchair Ramp Cost by Material

When you calculate the average cost of building a wheelchair ramp, $50 to $250 per linear foot will be attributed to the material. Buying a new ramp means you need to choose the material that works best for your home. You can choose wood, concrete, steel, aluminum, and rubber ramps. One of the main things to keep in mind is how sturdy you need the ramp to be. If used for just one wheelchair user or a lighter load, this may influence which material you wish to use, the same for if it will be used for multiple wheelchair users several times a day. The table below shows the average costs per linear foot of popular ramp materials.

| Material | Cost per Linear Foot (Materials Only) |

| Rubber | $50 - $150 |

| Wood | $100 - $250 |

| Aluminum | $150 - $200 |

| Composite | $150 - $200 |

| Concrete | $200 - $250 |

| Steel | $200 - $250 |

Rubber Ramp

A rubber wheelchair ramp is one of the most affordable options, priced around $50 to $150 per linear foot. This material should only be used for short thresholds or mini ramps, as it’s not as durable as other options. A long rubber ramp would not be strong enough to safely bear the wheelchair and user weight, especially for the taller height of multiple steps. Rubber is non-sticky and slip-resistant, making it a good choice for shower ramps and other indoor areas. It’s also easy to clean with a broom or hose as required, which is why some homeowners feel it's more functional than fashionable.

Wooden Wheelchair Ramp

The cost to build a wood handicap ramp is $100 to $250 per linear foot on average. The benefits of this ramp material include its affordability and easy installation. Plus, wood is widely available at most home improvement stores, so no matter where you live, your installer should be able to find the desired type of wood. One thing to keep in mind with wood ramps is they need more maintenance. An extra coat of primer every few years helps to stop warping and rotting that could make the ramp uneven. You will also want to add a slip-resistant coating for traction during wet weather.

Aluminum Wheelchair Ramp

Metal handicap ramps such as aluminum average $150 to $200 per linear foot. The aluminum handicap ramp prices tend to be slightly more affordable than concrete or steel. Aluminum brings certain advantages to the table, like high strength and corrosion resistance. Something to remember is lightweight aluminum bends and wobbles more easily. That’s why annual checks are important to make sure the ramp is still sufficiently sturdy, and no nuts or bolts are loose. You can also buy a prefabricated aluminum ramp for $100 to $800 on average.

Composite Wheelchair Ramps

A ramp made of composite costs between $150 and $200 per linear foot. Composite solves the common problems with some other materials. The material gives extra protection from moisture, so the ramp will not warp and allows the wheelchair to roll smoothly on the surface. The material is much more rigid than wood and resistant to fading, rotting, and insects. However, find a composite ramp with a full slip-resistant cap to ensure the material will be safe for use.

Concrete Wheelchair Ramp

The average concrete ramp cost per linear foot is between $200 and $250 per linear foot. It’s on the more expensive side, but it’s extremely durable, making it a good choice for permanent accessibility solutions. Another reason why homeowners often opt for the higher concrete ramp cost per square foot is they are robust and offer an aesthetic appeal. These ramps match with the rest of the house and the driveway. Keep in mind that the total cost of a concrete handicap ramp is often higher, with added labor for pouring and setting the concrete. If you need to remove this structure in the future, it can be difficult and pricey. As long as you want a driveway or porch ramp that lasts for 10 to 20 years, then the higher concrete wheelchair ramp cost may be worth it.

Steel Wheelchair Ramp

Steel wheelchair ramp prices average between $200 and $250 per linear foot. Despite the similar pricing, a steel ramp is not as permanent as a concrete one but still offers great stability for regular wheelchair use. One of the biggest benefits is that galvanized steel works well in outdoor areas to add texture traction for safe movement. One possible downside is the possibility of corrosion and rust. On the other side, steel dries off quickly to avoid rotting that often affects wood.

Labor Cost to Build a Wheelchair Ramp

Generally, masonry professionals charge between $60 and $90 per hour for a concrete ramp based on the location and scope of the job. A carpentry professional for wooden wheelchair ramps may be slightly less expensive, around $50 to $75 per hour. Professional ramp builders and installers produce a high-strength ramp that lasts longer than a DIY version. The van wheelchair ramp installation cost done by professionals is higher. Experienced ramp builders can also efficiently construct a safe ramp customized for the wheelchair user.

The building process and wheelchair ramp installation cost include an initial evaluation of the site for measurements so the design can be drawn up and approved. This is especially important for disability safety and ensuring the ramp meets all permit requirements and code regulations. The building process can take anywhere from a few hours to a few days or weeks, depending on the design.

Labor costs vary slightly by state and the size of the ramp project. Depending on the company, your professional installer may work solo or with several contractors on-site, affecting the labor costs. Installing a prefabricated aluminum ramp could be done in several hours. However, building a 50-foot ramp down a steep driveway with multiple runs and turns would take much longer.

Ramp Cost by Type

Many different types of wheelchair ramps are available for your home project. The material cost to build a ramp ranges from $50 to $6,000. Some ramps are permanently installed in one spot of the house, while others are portable or partially portable. The type of ramp you install depends on your individual needs. This depends greatly based on where you need it installed, how often it’s going to be used, maintenance preferences, budget requirements, and much more. This table highlights the average cost of materials for each type of ramp.

| Type | Ramp Cost (Materials Only) |

| Threshold | $50 - $1,300 |

| Portable | $100 - $2,000 |

| Semi-Permanent | $350 - $2,000 |

| Modular | $500 - $5,000 |

| Permanent | $800 - $5,500 |

| Custom | $1,000 - $6,000 |

Threshold Ramp

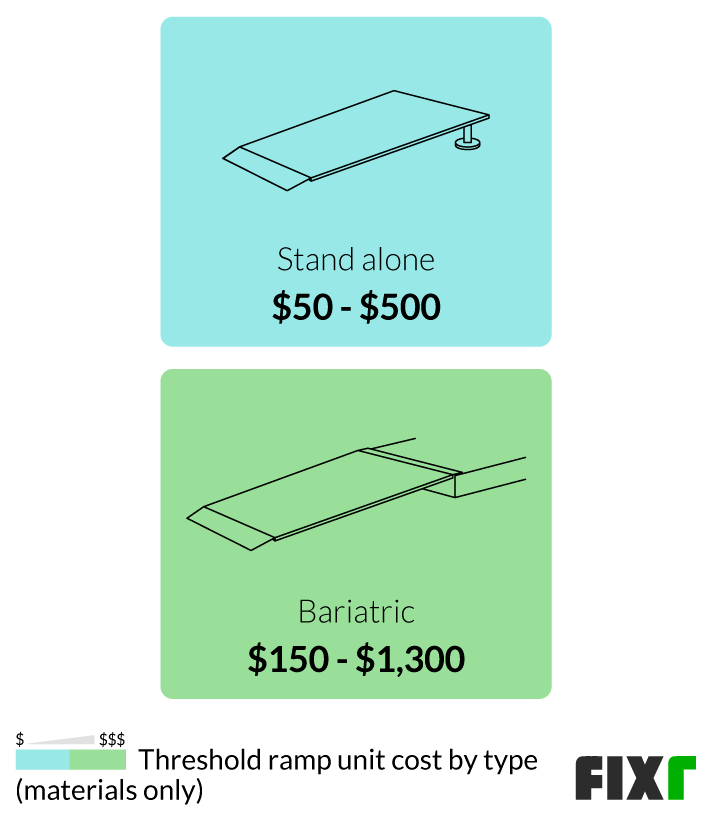

Threshold ramps are short, small ramps used for doorways and entryways, ranging in price from $50 to $1,300. They are a good option if the door frame is higher than the floor. The two main materials used for threshold ramps are aluminum and rubber. Their average cost is $50 to $200 for aluminum threshold ramps and $100 to $600 for rubber models. Aluminum ramps are high-strength and have a slip-resistant surface that holds up well against rust and corrosion. Rubber is another eco-friendly and sturdy material for short ramps in doorways and split-level stairs. Just remember that ramps without slip-resistant coating can be slippery.

There are two different threshold ramps: stand-alone ramps and bariatric ramps. The average price for stand-alone threshold ramps is $50 to $500. They are self-supporting ramps with an adjustable leg design and slip-resistant surface. They can accommodate up to 9” in height and between 500 and 700 pounds. Bariatric ramps, on the other hand, cost $150 to $1,300 and are designed to bear heavier loads safely. They may be wider and longer, with a heavy-duty look, but they minimize the risk of slipping and can be attached to the doorway.

| Threshold Ramp Type | Unit Cost (Materials Only) |

| Stand Alone | $50 - $500 |

| Bariatric | $150 - $1,300 |

Portable Ramp

Portable ramps range from $100 to $2,000 and are ideal for renters or people who are temporarily disabled following an injury or an accident. Fixed ramps may be a better idea for people who use a wheelchair for life. Portable ramps are convenient as they can be moved from room to room or used for traveling. They range from 3 to 10 feet in size. Some people also choose to test out portable ramps before installing a permanent ramp in their homes.

There are several types of portable ramps on the market. Folding ramps, also known as suitcase or multi-fold ramps are usually made of aluminum and have different weights. Telescoping ramps are adjustable in height and length and have a locking mechanism that keeps the tracks in place. Roll-up ramps are similar to folding ramps, but instead of folding, they roll up for easier storage and have different length varieties. Track ramps are also made of lightweight aluminum and can be folded or opened up but have two individual tracks that align with the wheels on both sides. Bariatric ramps are designed to support heavier weights with several design varieties. The table below shows the average unit price of each portable ramp type.

| Portable Ramp Type | Unit Cost (Material Only) |

| Folding | $100 - $600 |

| Telescoping | $150 - $500 |

| Roll-Up | $200 - $1,000 |

| Track | $200 - $2,000 |

| Bariatric | $400 - $800 |

Semi-Permanent Ramp

A compromise between permanent and portable ramps, semi-permanent ramps cost between $350 and $2,000. Instead of being firmly anchored into the ground like permanent ramps, semi-permanent ones are safely installed but easier to remove if need be. They may not require as many customizations and approval as fully permanent ramps. A modular aluminum ramp is one of the most common semi-permanent accessibility solutions.

Modular Wheelchair Ramp

Modular ramps cost between $500 and $5,000 and are generally less expensive than their custom counterparts. These ramps are typically prefabricated and delivered in several sections for your contractor to put together quickly. Modular ramps function as fixed ramps but can be disassembled, moved, and set up again. Pathway ramps are one example of modular ramps. They offer multiple configurations combining ramps, platforms, and stairs and often come with handrails and other safety features. Aluminum and steel are the most common materials for modular ramps that can be modified to suit your property. They generally require low maintenance and are ideal for temporary or semi-permanent use. Accurate measurements are key to success with a modular ramp, so make sure you have a reputable installer on hand to help with this project.

Permanent Wheelchair Ramps

Permanent wheelchair ramps for homes cost between $800 and $5,500. They can be made out of wood, aluminum, steel, concrete, or rubber. The main benefit of permanent ramps is that they offer the highest level of stability and are extremely reliable. However, they are firmly positioned in place and cannot be moved to other areas of the house or other properties without considerable labor and removal costs. Households with regular wheelchair users or several seniors often find this to be a sensible investment.

Custom Ramp

Custom ramps cost between $1,000 and $6,000. A custom ramp is usually built by a contractor and is permanently anchored into the ground. These ramps can be personalized and designed to suit your property and individual needs with the help of a professional. You can choose from wood, aluminum, steel, rubber, and concrete as the material. The number of runs and turns can also be adjusted for the length and slope of your ramp.

Wheelchair Ramp Cost by Location

The average cost to build a wheelchair ramp varies depending on where you want to install it. Building a wheelchair ramp costs $200 to $2,000 for a short indoor ramp for one room. However, your cost may increase to $1,200 to $5,000 for a ramp for the front porch or driveway. Typically, indoor ramps are shorter, less than 10 feet in size, and less expensive to install than outdoor ramps that can go up to 20 feet or more. This is not only because less material and time are spent but also because the material used for indoor ramps is not as sturdy and weather-resistant as outdoor ramps. It is often less expensive than the same material used outdoors.

Pricing depends greatly on the length and material of the ramp and the needs of the ramp user. Some users need a handicap ramp only in the rooms they regularly use. Others may need it to access outdoor areas. Some users need a wheelchair ramp everywhere in the house. It is good to consult with your ramp installer to discuss your needs. The table below shows how much you can expect to spend on a ramp when installed indoors versus outdoors.

| Location | Ramp Cost (Material Only) |

| Indoor | $200 - $2,000 |

| Outdoor | $1,200 - $5,000 |

ADA Ramp Requirements

The ADA (Americans with Disabilities Act) provides certain codes, guidelines and important ramp specifications to consider when installing ramps. These guidelines are required for ramps on public property and commercial buildings such as nursing homes and care centers. Though most homeowners are technically not required to adhere to these standards when building a ramp for private residential use, they are recommended and serve as an excellent reference point for wheelchair ramp design plans.

ADA recommends that each handrail is installed within 34 to 38 inches from the surface and with no less than 36 inches clear width between each handrail. Rails are required on both sides when ramps rise six inches or more or are more than 72 inches long. Level landings must be at the top and bottom of the ramp, with at least 60 inches of length and the same width as the ramp. Ramps are specifically designed for the type of weight they are intended to support. For example, some ramps are built only for manually operated wheelchairs, while some are meant only for electric wheelchairs.

Depending on the design of the house, some ramps may require turns or runs, especially if it is a longer ramp spanning a taller height. Each turn platform needs to be at least 5 feet by 5 feet to accommodate turning wheelchairs. The ADA requires a rest or turn platform for every 30 feet of wheelchair ramp. It also recommends that the slope of a ramp in new construction should not exceed 1:12. The maximum rise for any run should not be more than 30 inches.

The landing at the bottom and top of each ramp should be as wide as the ramp leading to it and have a minimum length of 60 inches. If the ramp changes direction at the landing, the landing size should be at least 60 inches by 60 inches. Ramps and landings with drop-offs should have edge protections like curbs (at least 2 inches), walls, railings, or projecting surfaces to ensure people do not slip or fall off. Side flares are a common choice for adding additional space to a top landing for easier navigation.

How Do You Calculate the Length of a Ramp?

To calculate the length of the ramp needed at your home, you need to measure the total rise from the bottom level to the top level. For example, if the ramp is for your front porch stairs, you need to measure the distance from the pavement to the porch floor. The total rise must be divided by the slope, which measures the steepness of the ramp. For safety, a lower slope is better. The ADA recommends a slope ratio of 1:12 or 8.33%. The slope may be slightly higher or lower based on the wheelchair user, weight, and level of independence.

When in doubt, you should always ask a professional how to determine ramp length for your property. Contractors can help you determine which type of ramp is best for your space and individual needs. Their measurements will also be more precise. They can suggest custom solutions to make your home safely accessible for wheelchairs. Professionals can help make your ramp ADA compliant.

Are Wheelchair Ramps Covered by Insurance?

Home ramps are a safety requirement for many residents who have limited mobility or use a wheelchair. The costs of this improvement project can add up, especially if someone is already paying hefty medical bills for their treatment. In some cases, financial assistance may be available for those who need a modular or permanent ramp at home. Below are a few of the main options to consider when financially planning to put a ramp in your home.

Medicare ramp coverage is often the first thing seniors and their families think of when paying for home ramps. This federal program provides health insurance for most adults 65 years and over. For the most part, traditional Medicare policies do not cover residential modifications and equipment upgrades. That’s because wheelchair ramps are covered in Medicare’s Durable Medical Equipment policy, which requires a licensed physician to declare the ramp a medical necessity.

Although older Medicare plans aren’t much help for home ramp installations, some seniors have better luck with the newer Medicare Advantage plans. Some plans cover supplemental benefits such as healthcare items that prevent injury, lower the likelihood of emergency care, or compensate for practical functions. People with metastatic cancer, rheumatoid arthritis, Alzheimer’s disease, and other forms of dementia and memory loss may qualify for special supplemental benefits through Medicare Advantage to help with home wheelchair ramps and other upgrades.

Medicaid ramps are a possibility for seniors with low income and people affected by a disability. Each state may have different Medicaid policies, but there are regular benefits and long-term nursing home care benefits. There are also waivers through Home and Community Based Services (HCBS). As an entitlement program, regular Medicaid typically only covers wheelchair ramps necessary for medical care. This is highly unusual, and few successful cases have had to go through court. Luckily, many states offer HCBS waivers to help with home modifications and adaptations such as wheelchair ramps.

Assistance for veterans includes the VA’s Cash and Counseling program, in which qualifying veterans select certain services and equipment within their care budget, such as wheelchair ramps. Home Improvement and Structural Alteration (HISA) grants are another option. This funding makes homes more accessible for veterans, whether their disability is due to their active service or normal aging.

Ramp Maintenance

Like any home feature, ramps require maintenance and cleaning to keep them in good condition. Cleaning and maintenance depend on the material. Check with your ramp installers for their most up-to-date recommendations. For example, a wooden ramp is susceptible to water damage. A metal ramp may experience rust over the years. That is why waterproofing and rustproofing are important, especially for these two materials.

Most ramps can be swept clean or vacuumed regularly to remove dirt and eliminate slip hazards. Hoses can be used to clean outdoor ramps when not in use. In addition to cleaning, you should watch for sagging, rotting, or loose bolts on your ramp. Generally, you can evaluate this yourself. If you have questions or think there is something seriously wrong with your ramp, it is best to get the professionals involved to inspect it.

Ramp Alternatives Cost

While wheelchair ramps are a worthwhile investment for many homeowners and families who need to safely navigate around the house, there are several alternatives to think about, such as wheelchair or scooter stairlifts. Similar to the lifts used in vans but with a special design for the higher heights of home stairs, these lifts are less expensive than the shorter and straighter staircase. A home stairlift installation costs between $3,000 and $5,000.

An even more expensive option is a home elevator, which averages around $35,000 to $60,000. The significant expense includes all the electrical and mechanical work required to ensure a safe elevator. While elevators are arguably the most attractive and convenient, ramps or stairlifts are much more budget-friendly while still offering a safe, reliable accessibility solution.

| Alternative | Unit Cost (Installed) |

| Stairlift | $3,000 - $5,000 |

| Elevator | $35,000 - $60,000 |

Enhancement and Improvement Costs

Ramp Lighting

Hiring an electrician to install additional ramp light fixtures costs $40 to $120 per hour. In-deck LED ramp lights cost $45 to $75 per eight-piece box and are a good fit for this purpose. Since normal porch lights or street lights may not provide adequate visibility, you may want to add additional lighting. Adding ramp lighting is a great way to make the ramp safer to use at all times. It also adds to the visual impact of the ramp.

Additional Considerations and Costs

- Permits. Check with your contractor to see what local permits, licenses, and codes you must have or meet in your city. Generally, you want to follow ADA recommendations, but you have a bit more flexibility for custom ramps in a private residential setting.

- DIY. Hiring an expert for ramp installation is in your best interest. While technically you could try and make a ramp on your own, you may be compromising the safety of this all-important home feature. A professional can engineer a custom-made ramp to suit your property and wheelchair requirements, including the right slope and long-lasting materials.

- Financing. Wheelchair ramps may be partially or fully paid for through financial options like state-based assistance, elder care loans, or non-profit community assistance programs. Check with your local government or disability/senior charities near you for more information.

- Convertible stair ramps. If you’re not sure about making a full ramp for a set of stairs, convertible stair ramps are one innovative idea to consider. As a temporary/movable ramp, these are attached to existing stairs. The pull of a lever or push of a button transitions the steps into a ramp. This machine flips the ramp material up at an angle to form a fully connected ramp. These aren’t that common on the market, but you may be able to find one near you for between $200 and $1,000.

- Ramp rental. Ramp rentals are a good temporary fix. You can rent a temporary ramp while waiting for a permanent one to be installed. Renting a wheelchair ramp is also a good idea if you just want to test it out and figure out which one would work best in your home. Rentals may assist if you’re moving to a new home as well. Ramp rentals cost between $100 and $300 per month and may come with a one-time installation cost from $200 to $800 depending on the design and the company.

- Slip prevention. Some ramp materials can become slippery, especially if outside and exposed to the elements like rain and ice. In this case, you may need slip prevention such as rubber matting, fiberglass strips, or anti-slip tape. Plan to pay $15 to $100 for slip prevention solutions.

FAQs

- Does Medicare pay for wheelchair ramps?

While traditional Medicare policies usually don’t reimburse the cost of wheelchair ramps, some new plans like Medicare Advantage may help with this project.

- Are ramps expensive?

Ramps can be expensive if you need a lengthy one or choose a material on the higher end. Custom-made ramps cost more than modular ones. Overall prices range from $50 to $6,000.

- Are ramps covered by insurance?

Many ramps are covered by insurance or government assistance programs, but it depends on your policy and where you live. Contact your insurance company or local government for more information.

- How wide does a wheelchair ramp have to be?

This depends on your property, the width of the doorways, and the wheelchair size. The ramp should be big enough to accommodate the wheelchair with ample space around it. Ramps should be a minimum of 36 inches wide or 42 inches for ramps with rails.

- What is the slope of a handicap ramp?

Handicap ramps should have a low slope for safety, around 1:12. For each vertical rise inch, there should be 12 inches or one foot of horizontal ramp.