Updated: January 27, 2026

Written by Dan Simms

Nieves Martinez is a writer and editor at Fixr.com, specializing in home improvement and construction content. With over five years of experience and a Master's degree in Digital Marketing, she collaborates with industry professionals to create clear, carefully reviewed cost guides and renovation resources that help homeowners make informed remodeling decisions.

Learn moreReviewed by Nieves Martinez

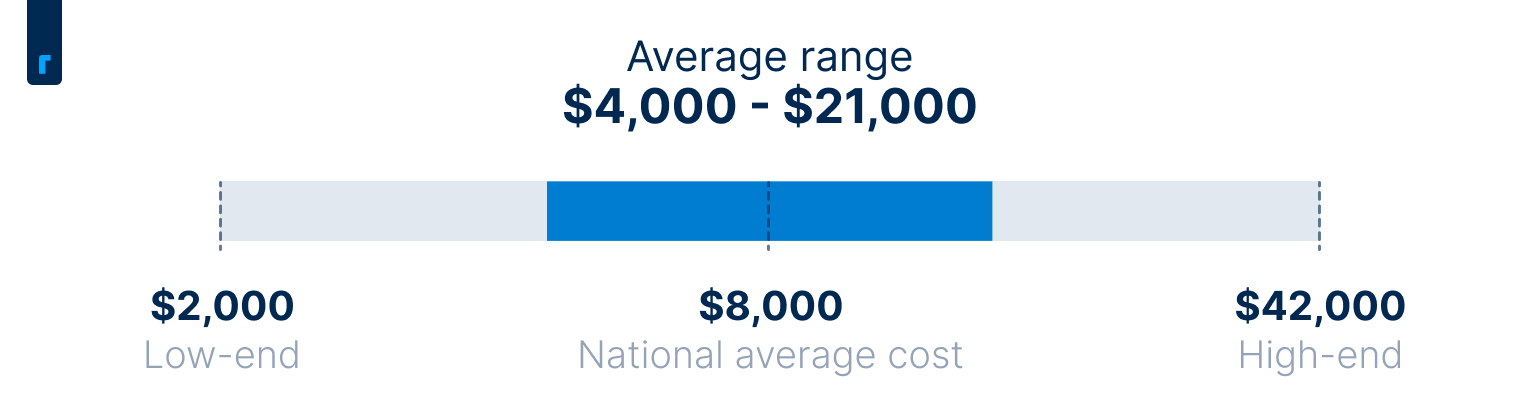

Flat roof replacement costs an average of $8,000, and most people pay somewhere between $4,000 and $21,000. This pricing would be for a standard 1,000 to 1,500-square-foot roof fitted with modified bitumen. Your price could climb to $42,000 or more if you have a larger, 3,000-square-foot roof and opt for a more expensive material, like thermoplastic polyolefin (TPO). Costs will vary depending on roof size, material, roof complexity, and labor costs in your area.

Flat roof designs are popular among modern residential structures. They avoid interior slopes, so they make for the most living space possible, they’re easy and safe to access for repairs and maintenance, and they’re some of the most affordable roof styles to replace.

Cost of Flat Roof Replacement

Flat Roof Replacement Cost per Square Foot

You could pay on average anywhere from $4 to $14 per square foot for flat roof replacement, including materials and labor. The specific cost per square foot for your project will depend mostly on the material you choose, but the size of your roof is the most significant cost factor overall. For flat roofs, the roof area is typically about the same as the home’s footprint.

Roof Size (Sq.Ft.) | Typical Cost Range |

1,000 | $4,000 – $14,000 |

1,500 | $6,000 – $21,000 |

1,700 | $6,800 – $23,800 |

2,000 | $8,000 – $28,000 |

2,500 | $10,000 – $35,000 |

3,000 | $12,000 – $42,000 |

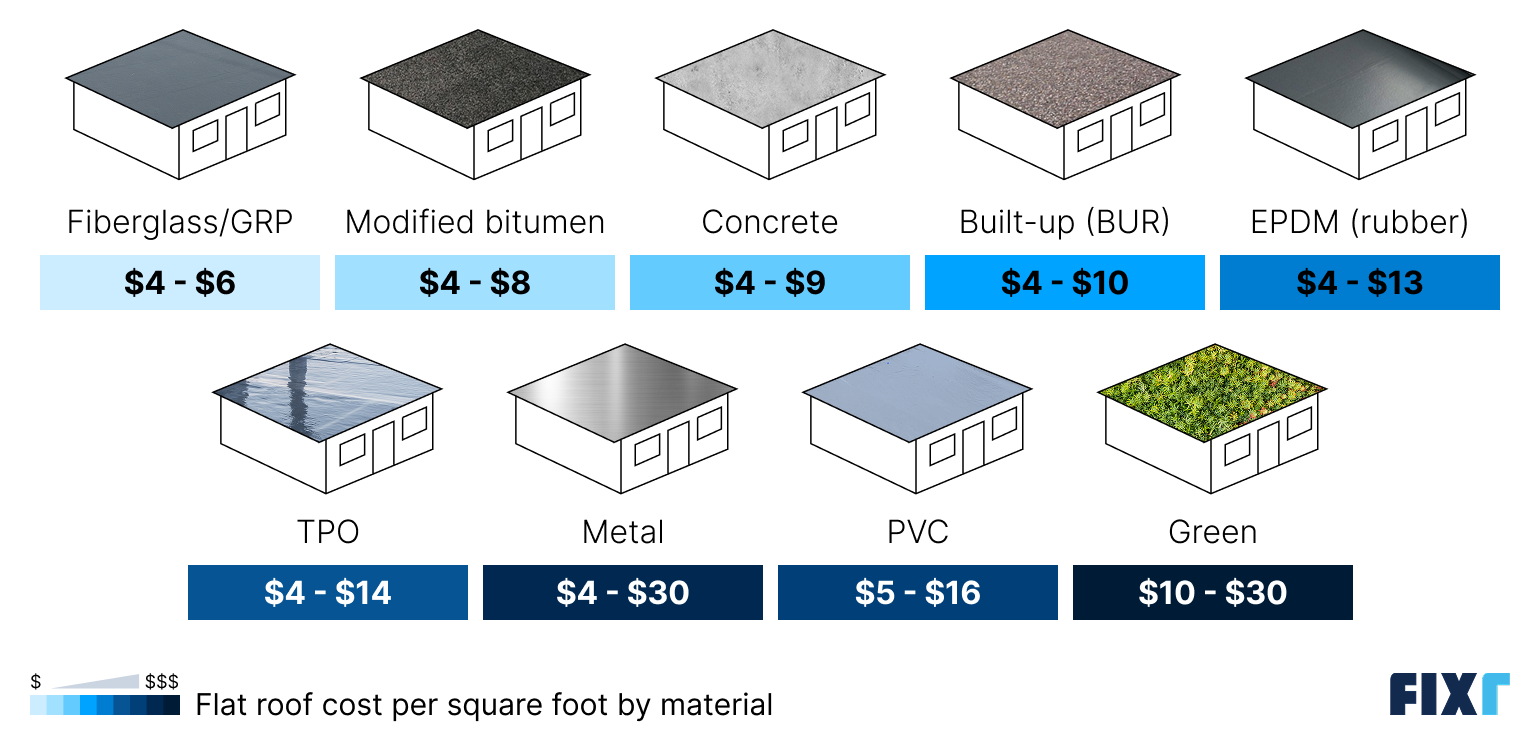

Cost of Replacing a Flat Roof by Material

There are many different materials you can choose for your flat roof, and since they all vary widely in the cost per square foot, the material will play an important role in your total flat roof replacement cost. Modified bitumen is one of the most affordable flat roof materials, but other options, like built-up roofing (BUR), EPDM, and TPO, provide varying levels of energy efficiency, ease of repair, durability, and longevity.

Material | Cost per Sq.Ft. |

Fiberglass/GRP | $4 – $6 |

Modified bitumen | $4 – $8 |

Concrete | $4 – $9 |

Built-up (BUR) | $4 – $10 |

EPDM (rubber) | $4 – $13 |

TPO | $4 – $14 |

Metal | $4 – $30 |

PVC | $5 – $16 |

Green | $10 – $30 |

Fiberglass or GRP

Fiberglass or glass-reinforced plastic (GRP) roofing is an increasingly popular flat roof option for small roofs. It’s made of fiberglass, as the name suggests, and it’s installed in a single piece of roofing, making it one of the most leak-resistant options. It can last for 20 to 30 years and costs just $4 to $6 per square foot, although costs can get prohibitively high for larger roofs. It requires minimal maintenance, but it can crack in colder weather.

Modified Bitumen

Modified bitumen roofing is similar to BUR, but the asphalt material is modified using polymers that enhance strength and durability. Modified bitumen roofing costs between $4 and $8 per square foot, as it’s less labor-intensive than BUR, which requires multiple layers. This roofing requires less maintenance than BUR, although it doesn’t last as long, with a lifespan of around 20 years, and it’s more expensive to repair.

Concrete

Poured concrete is an uncommon option for flat roofs because of its weight. Most buildings will need structural reinforcement to be able to support a concrete roof. If yours can, though, concrete has a low risk of leaking, is easy to repair, and costs just $4 to $8 per square foot to install. Concrete roofs are fire-resistant and extremely durable, and they can last for 50 to 100 years with proper maintenance. They’re also the safest flat roof material to walk on.

Built-up (BUR)

Built-up roofing is a common and affordable option for flat roofs, and it costs between $4 and $10 per square foot. The roofer will create the roof on-site by layering asphalt and roofing felt. It’s a low-cost solution for flat roofs and is very easy to repair, but it requires regular maintenance and inspections to avoid leaks. BUR lasts for 15 to 30 years with good maintenance.

EPDM (Rubber)

Ethylene propylene diene monomer (EPDM) roofing is a single-ply roofing system made of rubber. The installation is faster and easier than with BUR and modified bitumen roofing, but the materials are more costly and push the installation cost to $4 to $13 per square foot. It’s reasonably durable and can resist punctures from blown debris, and it lasts for up to 30 years. However, it’s hard to repair, and the seams, which are usually glued, are prone to leaking.

TPO

Thermoplastic polyolefin (TPO) roofing is one of the most common flat roof materials, valued for its balance of affordability and performance. It generally costs between $4 and $14 per square foot. TPO membranes are lightweight, flexible, and highly resistant to tears, punctures, and mold. The material’s main drawback is variability in quality among manufacturers, which can affect long-term durability. On average, a TPO roof lasts 20 to 30 years. Its bright white surface reflects sunlight, which helps reduce cooling costs in hot climates.

Metal

Metal roofing is an option for low-slope roofs that are commonly referred to as flat roofs, but you need more of a slope than you would for most other options. Metal roofing is extremely durable, and some materials can last for 50 to 70 years. Metal roofing is the most expensive, ranging from $4 to $16 per square foot in most cases and up to $30 if you choose high-end copper. Metal can reflect solar heat, making it a good option in hotter climates.

PVC

Polyvinyl chloride (PVC) roofing is a single-ply membrane system known for its strength, flexibility, and resistance to chemicals. Installation is relatively straightforward, though the higher-quality material drives up the price, which typically ranges from $5 to $16 per square foot. PVC membranes are especially durable, offering excellent resistance to water, fire, and punctures. However, they can become brittle over time in very cold climates if not properly formulated. A well-maintained PVC roof can last 20 to 30 years.

Green Roof

A green roof is one that involves multiple protective layers, usually including imprinted rubber sheets, root barriers, waterproof membranes, and soil that can support live plant growth. These are the most eco-friendly flat roof options, and they’re considered cool roofs because they transfer minimal heat into your building’s interior. Green roofs are expensive, costing between $10 and $30 per square foot, and they’re extremely heavy, so they often require structural reinforcement. They can last up to 30 years with good maintenance and will reduce heating and cooling costs in the meantime.

Labor Costs

Labor will make up a significant portion of your flat roof installation costs, although the specific percentage of the total ranges from around 20% up to nearly half of the total, depending on the type of flat roof you choose. In most cases, the cost for labor alone will fall between $3 and $7 per square foot. However, roofers may also charge by the hour, typically ranging from $30 to $130 per hour, with an average of about $75, depending on location, experience, and job complexity.

Labor costs will be higher for something like built-up roofing, a product that’s entirely crafted on-site in a labor-intensive process. They’ll be much lower for something like TPO roofing, which is relatively easy to install and work with.

Cost Factors

While the size of the roof, the flat roof material you choose, and the labor costs in your area will largely determine how much your flat roof replacement will cost, there are many other minor factors that can affect your total.

Geographic Location

Where you live will play an important role in your labor costs, which usually range widely based on the local cost of living. Expect to pay more for labor in and around major cities, as well as in states with a higher cost of living. This is especially true if you choose a labor-intensive roofing material, like BUR.

Old Roof Removal and Disposal

In many situations, the old flat roofing material must be removed before installing a new roof. The removal and disposal of debris typically costs $1 to $5 per square foot, or around $1,000 to $5,000 for an average-sized roof. Costs may be higher for heavier materials, such as concrete or green roofing. Since some contractors include this in their overall estimate, it’s important to review quotes carefully before budgeting separately.

Roof Condition and Repairs

When your roofer removes your old roof, they may find unexpected damage from leaks or old age. Replacing underlayment, insulation, or decking could add hundreds or even thousands of dollars to your total, depending on how bad the damage is.

Roof Complexity and Accessibility

The complexity of your roof can increase costs. Roofs with unusual shapes, chimneys, vents, or parapet walls make installation take longer, while large homes add difficulty in moving materials, driving up labor costs.

Installation Method

There are three general ways to install a flat roof. Some methods are only possible with certain flat roof products, so costs will vary among the different materials, too:

A ballasted flat roof is just roofing material held in place with gravel, rocks, or other heavy materials, and is the easiest and most affordable to install.

A fastened flat roof is usually the most expensive because every penetration needs to be sealed and waterproofed.

A fully-adhered flat roof falls somewhere in the middle, as it’s time-intensive to adhere but requires less sealing than a fastened roof.

Permits and Inspections

In most cases, you’ll need a permit to replace your flat roof. Permit fees range quite a bit, depending on the fee schedule your local building department uses, but most building owners can expect to pay permit fees between $150 and $600. If you’re switching roof types and need other changes, like structural reinforcement, you may face higher fees for additional approvals and added flat roof inspection costs.

Upgrades and Add-ons

Many homeowners will couple flat roof replacement with add-ons to improve energy efficiency, drainage, and leak protection. Some common add-ons include upgraded insulation for improved efficiency, a new system for better drainage, and new flashing for leak protection. These can add hundreds or thousands of dollars to your replacement costs.

Type/Design

There are four main types of flat roof designs, which vary based on where the layers of insulation, waterproofing membrane, and roofing go. Your costs can vary based on the design, as insulation and decking replacement costs can vary based on the type.

Warm roofs have insulation above the structural deck.

Cold roofs have insulation under the decking and a ventilation space.

A hybrid setup combines the warm and cold approaches.

An inverted flat roof has insulation above the waterproofing membrane.

Repair vs. Replacement

Replacing a flat roof can get expensive, so it may be worthwhile to consider a repair rather than a full replacement. Repairing a flat roof costs an average of around $700, while a new flat roof costs an average of $8,000. Repairs will almost always be more affordable, but which is better for you depends on the state and age of your current roof.

If your existing flat roof is less than a decade old and has only sustained localized damage, then a repair is usually the best option. This is especially true if you have an easy flat roof to repair, like a built-up roof that can be patched. If you’ve experienced ongoing issues with leaks, have widespread damage, or your roof is nearing its useful lifespan, splurging on a full replacement is going to be the better option in the long run and can also provide improved energy efficiency and greater peace of mind.

DIY vs. Hiring a Professional

Replacing a flat roof may seem like a straightforward project, but it’s complex and dangerous, and even minor mistakes can lead to major property damage since your roof has minimal slope and can easily collect water. A single seam that isn’t sealed properly or a small area that doesn’t have the right slope can lead to major damage, which can end up costing you more in repairs and mold remediation than you’d spend on a professional roof installation in the first place.

Hiring a roofing contractor will absolutely be more expensive, but you’ll keep your manufacturer’s warranty intact, you’ll often get a labor warranty, and you’ll have a much lower risk of issues leading to severe property damage from water leaks or inefficiencies from poor insulation installation. All roofing is best left to a pro, but especially flat roofs, which come with a greater risk of leaks.

How to Save on Your Flat Roof Replacement

While DIYing to save on labor costs isn’t a good idea, there are some other ways you can save on your flat roof replacement costs.

Choose your roof material carefully: You can save by going with a more affordable material, but think about the climate and severe weather conditions your roof will see, and ask a local roofer what material provides the best value and durability in your area.

Think about efficiency: Different flat roof materials provide varying levels of insulation and energy efficiency, too, so the choice can affect your ongoing heating and cooling costs.

Look for rebates and other incentives: In some areas, certain flat roof materials can improve energy efficiency so much that they qualify for efficiency incentives. Check the Database of State Incentives for Renewables and Efficiency (DSIRE) to see if there are perks in your area.

Invest in insulation and drainage: New insulation can improve your building's energy efficiency, while upgraded drainage helps prevent water from accumulating, reducing the risk of expensive leaks and structural damage.

Schedule during the off-season: Roofers are busiest in the summer and fall, so you might see discounts on labor costs and even material costs if you can wait until late winter or early spring. Just don’t put off your replacement if you’re experiencing signs of a roof leak, as the potential damage will cost more than any discounted labor rates.

Get multiple quotes: Get at least three estimates for your roof project. You can then compare to find the best value and rule out quotes that come in unusually high due to inflated material or labor costs.

FAQs

The average cost to replace a flat roof is $8,000, and most people pay between $4,000 and $21,000. You may need to add $1,000 to $5,000 to that number if your roofer doesn’t include the cost to remove your old flat roof in their estimate.

Flat roofs last an average of 20 years, and most have a lifespan ranging from 15 to 30 years, but it depends on the material. Metal and concrete flat roofs can last for 50 to 100 years, while some TPO roofs may last just 10 years. Flat roof lifespan also depends on the climate in your area and how much physical wear and tear it experiences from foot traffic and blown debris.

You should replace your flat roof every 15 to 20 years, which is the typical lifespan of most flat roof materials. However, the timeline varies based on the installation quality, the material, and the weather conditions in your area. Some flat roofs, like those made from concrete or metal, may only need replacement every 50 years, while TPO roofs in extreme climates might need to be replaced once every 10 years.

On average, flat roof replacement takes between 3 and 7 days, but the timeline varies on either end depending on your existing roof type, the size of the roof, the complexity of your roof, and the material you’re installing. Something like built-up roofing will take longer because it involves a more labor- and time-intensive installation process, while single-ply membranes are generally pretty easy to install and may just take 2 to 3 days.

Modified bitumen is the most affordable flat roofing material. Modified bitumen costs between $4 and $8 per square foot, and while fiberglass or GRP roofing costs between $4 and $6 per square foot in most cases, it’s not suitable for larger areas and can get much more expensive the bigger you go. More important than upfront cost, though, are suitability for your climate and longevity, so be sure to think about durability and lifespan when deciding on a material.

It’s almost always cheaper to repair a flat roof than it is to replace it. Flat roof repair costs an average of $700, while a full flat roof replacement costs an average of $8,000. Repairs can get even more affordable for built-up roofing and modified bitumen, both of which are relatively easy to patch. Just be sure to ask your roofer if a repair is viable, as a replacement could end up saving you money on ongoing repairs and potential damages in the long run.

The best replacement for a flat roof is usually single-ply membrane roofing, such as TPO or EPDM. TPO is popular for its heat reflectivity and energy efficiency, while EPDM offers a durable, lower-cost option. Both resist leaks well and typically last 20–30 years, making them the modern industry standard.