Updated: January 26, 2026

Written by Laura Madrigal

Nieves Martinez is a writer and editor at Fixr.com, specializing in home improvement and construction content. With over five years of experience and a Master's degree in Digital Marketing, she collaborates with industry professionals to create clear, carefully reviewed cost guides and renovation resources that help homeowners make informed remodeling decisions.

Learn moreReviewed by Nieves Martinez

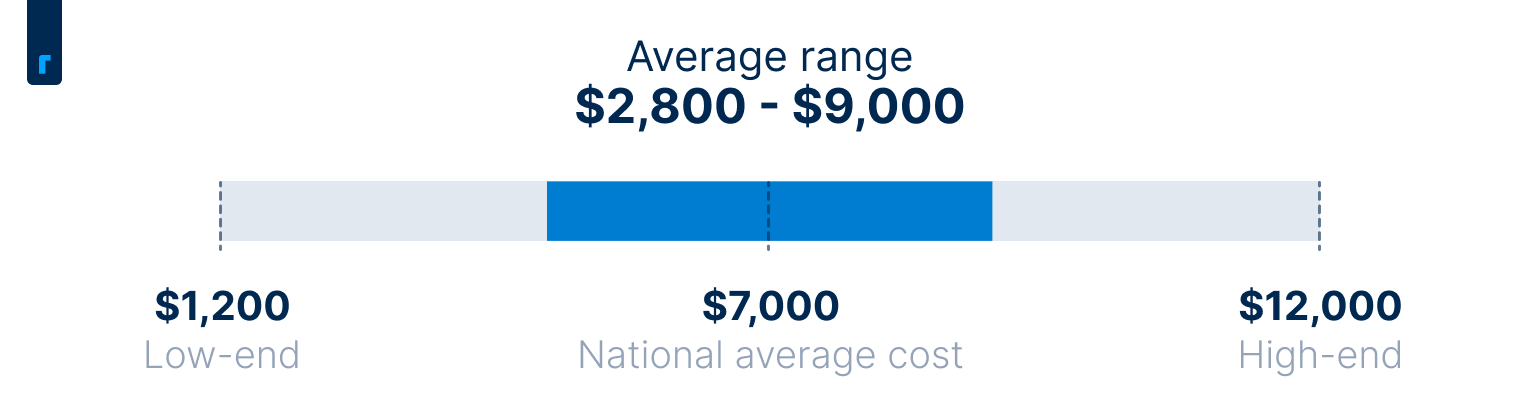

The average cost of a propane boiler installation is $7,000, with most homeowners spending between $2,800 and $9,000. Prices range from as little as $1,200 for a standard model in a small home to as much as $12,000 for a high-efficiency model with full system upgrades.

If you live in an area without natural gas service, a propane boiler system can be an efficient way to heat your home. These boilers use propane (LPG) stored in tanks to heat water for hydronic or steam systems. They come in several types and sizes, with costs depending on efficiency, materials, and installation needs.

Propane Boiler Costs

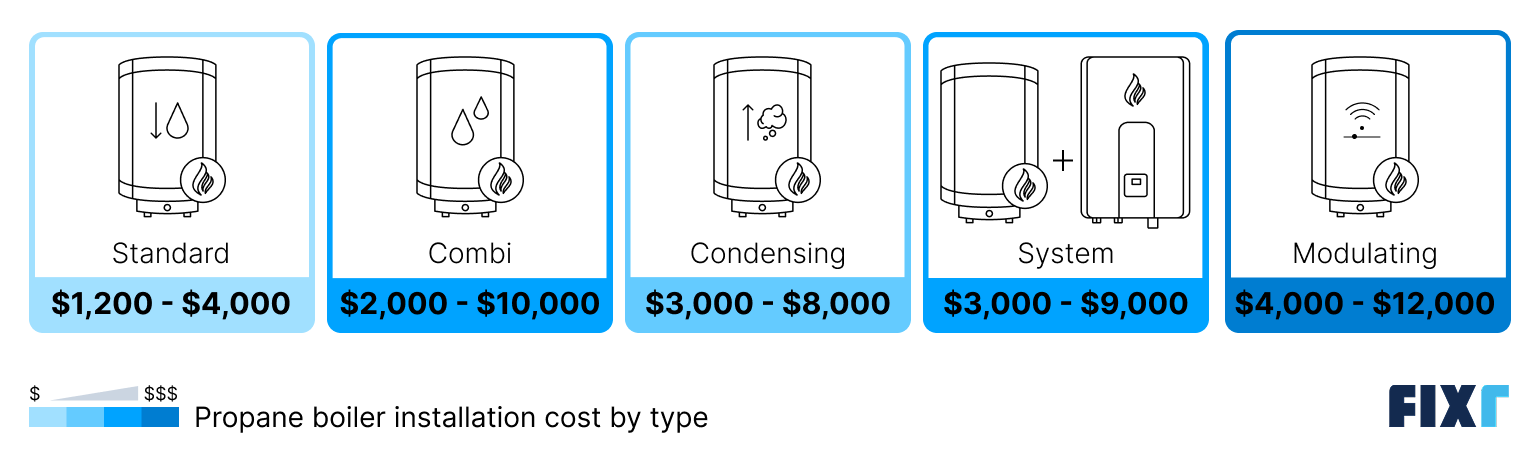

Propane Boiler Cost by Type

The type of propane boiler you install has the biggest impact on overall cost, efficiency, and long-term performance. Each type is designed for different household needs, so the best option depends on your home size, energy goals, and budget.

Type | Average Installed Cost |

Standard | $1,200 – $4,000 |

Combi | $2,000 – $10,000 |

Condensing | $3,000 – $8,000 |

System | $3,000 – $9,000 |

Modulating | $4,000 – $12,000 |

Standard Propane Boiler

These are the most common and affordable types of heating systems, using cast iron or aluminum heat exchangers. They provide reliable heating but lose more energy through exhaust, typically reaching 80–94% efficiency rating. With an average installed cost of $1,200 to $4,000, they are a good choice for homeowners who want a lower upfront investment and don’t require maximum efficiency.

Condensing Propane Boiler

Expect to pay between $3,000 and $8,000 for a condensing propane boiler. Condensing models capture and reuse heat from exhaust gases, boosting efficiency up to 98%. They require stainless steel heat exchangers and a condensate drain to handle acidic water. While more expensive, they reduce monthly fuel bills and are ideal for energy-conscious households.

Combi Boiler

A combi boiler provides both home heating and domestic hot water in a single compact unit. They save space by eliminating the need for a separate water heater, making them popular in smaller homes, condos, and apartments. However, they may struggle with high simultaneous water demand (like multiple showers). Combi boilers usually cost between $2,000 and $10,000 installed.

System Boiler

These boilers work with a separate hot water cylinder, supplying heating and hot water to larger households. They provide steady hot water for multiple taps at once, which is great for families. However, they require more installation space and slightly higher upfront costs, typically between $3,000 and $9,000.

Modulating Boiler

Modulating boilers automatically adjust their output to match your home’s heating needs in real time. This means greater comfort, less fuel waste, and longer system life compared to traditional on/off boilers. They are among the most efficient options but also fall on the higher end of the price range, with costs ranging from $4,000 to $12,000.

Propane Boiler Cost by Home Size

The square footage of your home has a direct impact on the size of the boiler you need and the total cost of installation. Larger homes require boilers with higher British Thermal Units (BTU) ratings, which are more expensive to purchase and install. The figures below assume average insulation and typical climate conditions.

Home Size (Square Footage) | Recommended BTUs | Installed Cost Range |

1,000 | 40,000 | $3,000 – $5,500 |

1,500 | 60,000 | $4,500 – $7,000 |

2,000 | 80,000 | $5,500 – $9,500 |

2,500 | 100,000 | $7,000 – $12,000 |

3,000+ | 120,000 | $8,000 – $15,000 |

What Size Propane Boiler Do I Need?

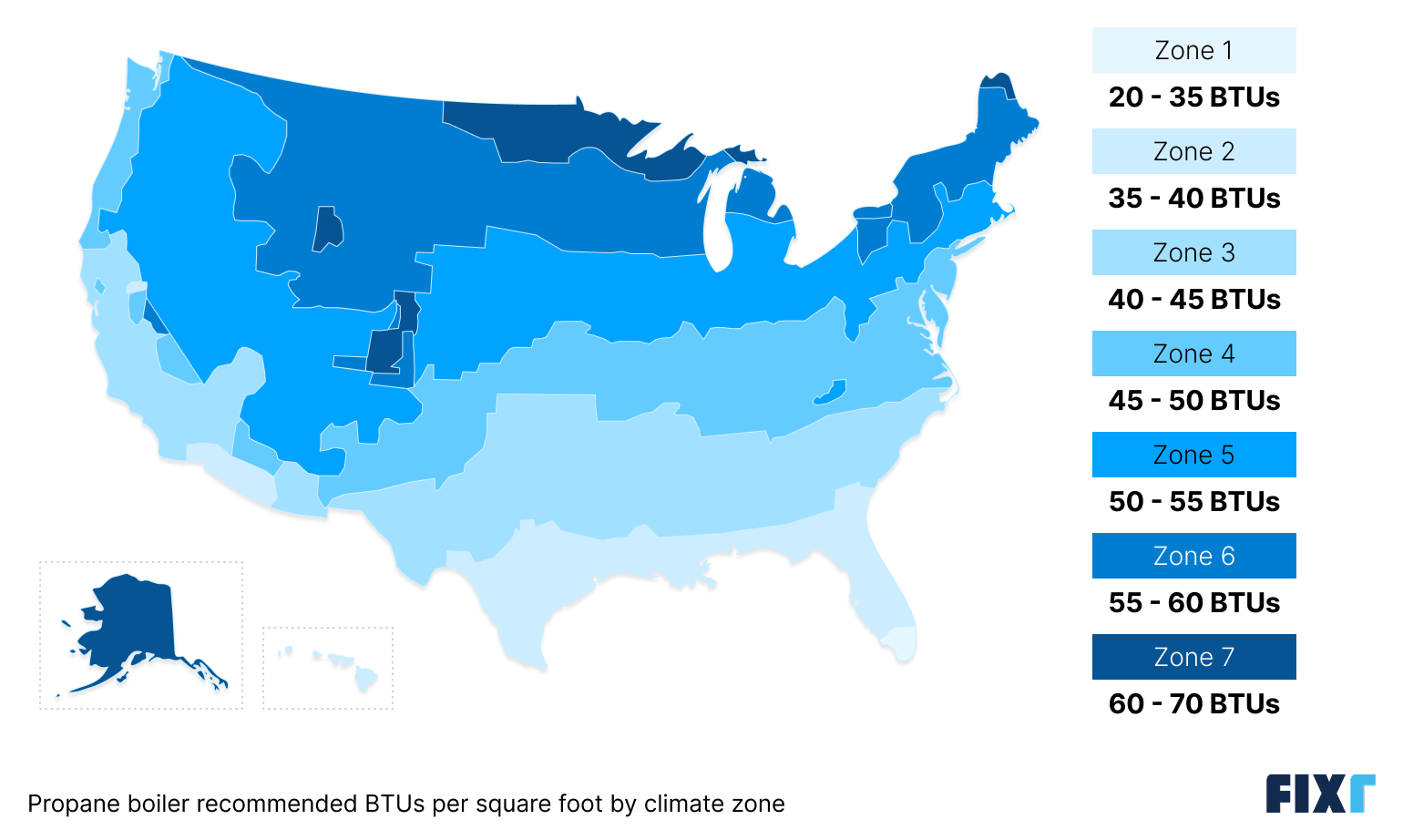

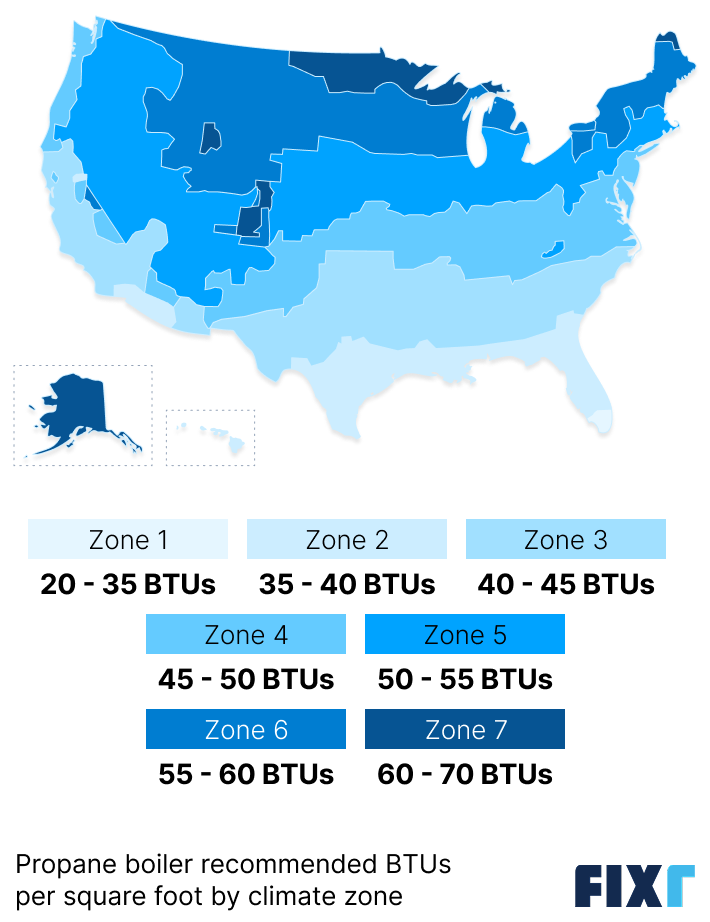

The "BTU per square foot" rule of thumb is a helpful starting point, but it’s only a rough estimate. The right size for your home depends on many factors, including insulation, ceiling height, window quality, and climate.

Choosing the correct size for your new boiler is essential. A unit that’s too small won’t keep up with demand, while one that’s too large wastes fuel and wears out faster, negatively impacting your operating costs. For accurate results, an HVAC professional should perform a heating load calculation.

Climate Zone | BTUs per Sq.Ft. | Example (2,000 Sq.Ft. Home) |

Zone 1 | 20 – 35 | 40,000 – 70,000 |

Zone 2 | 35 – 40 | 70,000 – 80,000 |

Zone 3 | 40 – 45 | 80,000 – 90,000 |

Zone 4 | 45 – 50 | 90,000 – 100,000 |

Zone 5 | 50 – 55 | 100,000 – 110,000 |

Zone 6 | 55 – 60 | 110,000 – 120,000 |

Zone 7 | 60 – 70 | 120,000 – 140,000 |

Propane Boiler Installation Cost

Installing a propane boiler typically costs $1,000 to $3,500 in labor, with the total price depending on the system’s size and the complexity of the setup. This process can be labor-intensive, involving plumbing, electrical work, gas line connections, and venting.

Replacing an old boiler usually costs about the same as a new installation. Some HVAC companies remove the old unit at no extra charge, while others may bill $200 to $500 for boiler removal and disposal. Professional installation is strongly recommended to ensure safe operation and maximum efficiency.

Repair vs. Replacement

When facing a problem with your propane boiler, the decision to repair or replace it depends on a few key factors: its age, its efficiency, and how severe the issue is.

Repairing is often the more economical choice for minor problems, especially if your boiler is relatively new. An average boiler repair can cost between $150 and $750, and this is often the best route if the boiler is in otherwise good condition.

Replacing is typically the better long-term investment if your boiler is more than 15 to 20 years old, needs frequent repairs, or isn't running as efficiently as it should. While boiler replacement costs more upfront, between $2,800 and $9,000, it can lead to lower energy bills and more reliable heating in the long run. Continual repairs on an old, inefficient unit can quickly add up, making a new, more reliable system a more cost-effective option over time.

Pros and Cons

Propane boilers have a number of benefits, but that does not mean there are no disadvantages to using them.

Pros

- + High efficiency (AFUE up to 98%)

- + Even, consistent heating

- + Can be installed off-grid

- + Compact options available (combi)

Cons

- - Higher upfront cost than some alternatives

- - Requires fuel storage tanks

- - Propane prices fluctuate

- - Regular maintenance required

Additional Costs and Considerations

Running costs: Propane averages about $2.70 per gallon in 2025. An 80,000 BTU boiler uses roughly 1 gallon per hour, which works out to about $2.70 an hour. Actual costs vary depending on the boiler’s efficiency, your local propane prices, and how often the system runs.

Propane tank installation or rental: Installing a tank costs $1,500 to $3,750, depending on size and whether it’s above or below ground. Rental options are available for $50 to $200 per year, which may be more cost-effective for some homeowners.

Maintenance: Professional servicing is recommended every few years and usually costs between $250 and $500. Regular maintenance helps extend the boiler’s lifespan and prevent costly breakdowns.

Permits and inspections: Many towns require permits to install or replace a boiler, costing $50 to $300. After installation, an inspection by a local authority is often mandatory to ensure the work meets all safety codes.

Cooling: Boilers only provide heat, so you’ll need a separate system for air conditioning. Adding central cooling typically costs between $5,000 and $12,000, depending on the size of your home and whether ductwork is already in place.

Brand: Oil boilers are available from many well-known manufacturers, with prices varying based on the boiler's size, features, and efficiency. Some of the most popular brands include Weil-McLain, Burnham, and Peerless.

Material: The heat exchanger material affects the cost and lifespan of an oil boiler. While durable cast iron units last for decades, highly efficient stainless steel models are more common in modern, high-efficiency systems.

DIY vs. Professional Installation

Propane boiler installation is not a recommended DIY project for homeowners. While you may save on the labor costs, the work involves complex plumbing, electrical wiring, and natural gas connections that can be dangerous if not handled properly. Mistakes can lead to serious hazards such as gas leaks, carbon monoxide poisoning, and electrical fires. For your safety, and to ensure the project is done correctly and legally, it is always best to hire a licensed and insured professional.

Ways to Save on Propane Boiler Costs

Installing a propane boiler can be a significant investment, but there are several ways to reduce your overall cost.

Upgrade to a high-efficiency boiler: While a high-efficiency boiler may cost more upfront, modern condensing models use less fuel to produce the same amount of heat, which can lead to substantial long-term energy savings on your bills.

Take advantage of rebates and incentives: Many states, utility companies, and manufacturers offer rebates and incentives for installing energy-efficient boilers. Be sure to check what is available in your area to help offset the initial cost.

Improve your home's insulation: Even the most efficient boiler won't save you money if your home is losing heat. Proper insulation in your walls, attic, and floors, as well as sealing drafts, can dramatically reduce heat loss, allowing your boiler to work less and lower your energy consumption.

Install a smart thermostat: A programmable or smart thermostat can help you save money by allowing you to set specific temperatures for different times of the day, ensuring you aren't wasting energy when you are away from home or asleep.

Get multiple quotes: Always get at least three quotes from different contractors. This allows you to compare pricing and find the best value, and to avoid contractors who have suspiciously high or low bids.

FAQs

Yes, propane boilers are highly efficient, with most modern models rated between 90% and 98% efficiency. They provide steady, even heat, making them a reliable choice for cold climates.

A propane boiler for a house costs about $7,000 on average, with prices ranging from $2,800 to $9,000, depending on the model and efficiency.

In many cases, propane is cheaper than oil because it burns more efficiently and produces more heat per gallon. However, actual savings depend on local fuel prices and your boiler’s efficiency.

The amount of propane depends on the boiler’s BTU output. Since one gallon of propane equals about 91,500 BTUs, larger boilers will use more fuel per hour than smaller ones.

Propane is more expensive than natural gas and must be stored in a tank on your property. Homeowners also need to monitor fuel levels and schedule deliveries to avoid running out.

Propane boilers are primarily rated by their Annual Fuel Utilization Efficiency (AFUE), a metric that indicates what percentage of fuel is successfully converted into heat versus what is lost through combustion. While standard-efficiency models typically range from 80% to 85% AFUE, high-efficiency condensing boilers can achieve between 90% and 98% AFUE. For a unit to be ENERGY STAR® certified, it must reach a minimum of 85% AFUE, though many premium models on the market today easily exceed 95%.