Updated: January 31, 2025

Written by Adam Graham

Adam Graham is a construction industry analyst with experience writing about home construction, interior design, and real estate. As a former member of the Fixr.com editorial team, he collaborated with industry experts and journalists to ensure accurate, up-to-date information for homeowners. His work has been featured in publications such as Better Homes and Gardens, the National Association of Realtors, and Insurance News Net Magazine.

Learn moreReviewed by Adam Graham

If you have a home on a lake, river, or other body of water, you likely need a dock to get full use of your property. They are not only the ideal place to fish and relax, but can also help you to gain better access to the water. Many of them are used as a launching point for swimmers or to help board a boat or personal watercraft. If you want to get into your boat without getting wet, a dock is a necessity.

When choosing a dock, homeowners have a wide range of options when choosing the shape, size, material, and configuration. Most homeowners fall more in the average range of $7,000 to $25,000. Most spend around $15,000 for a 360 sq.ft. stationary L wood dock with cedar deck. Docks vary widely in cost, with lower-end 120 sq.ft. floating dock with softwood deck running as low as $1,800. Large, cantilevered articulating docks cost as high as $65,000.

Average Cost to Build a Dock

| Dock Prices | |

| National average cost | $15,000 |

| Average cost | $7,000-$25,000 |

| Low-end | $1,800 |

| High-end | $65,000 |

Dock Cost per Foot

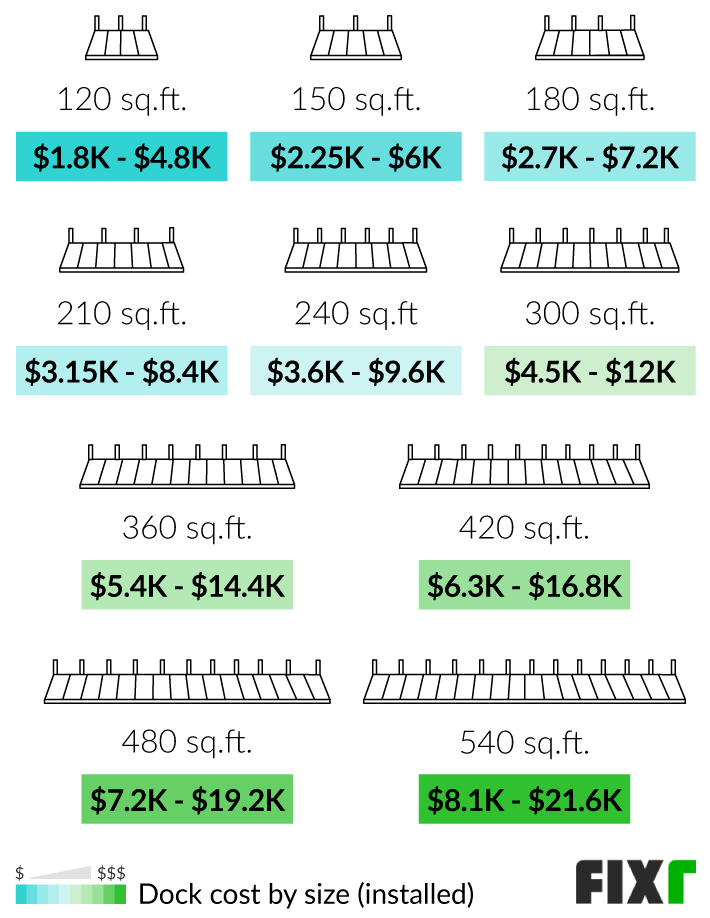

The cost of your dock largely depends on the number of square feet being installed, but the average cost per square foot ranges from $15 to $40, averaging $30 per sq.ft. These prices include the cost of the materials and labor. In general, the longer it is, the more material will be used and the longer the labor will take. Additionally, the water may become deeper the farther the it extends, leading to added cost. Two primary types will be priced by square foot--piling and floating. Below you will see the average cost per square foot, ranging from $1,800 to $21,600.

| Square Footage | Average Cost (Labor Included) |

| 120 sq.ft. | $1,800 - $4,800 |

| 150 sq.ft. | $2,250 - $6,000 |

| 180 sq.ft. | $2,700 - $7,200 |

| 210 sq.ft. | $3,150 - $8,400 |

| 240 sq.ft. | $3,600 - $9,600 |

| 300 sq.ft. | $4,500 - $12,000 |

| 360 sq.ft. | $5,400 - $14,400 |

| 420 sq.ft. | $6,300 - $16,800 |

| 480 sq.ft. | $7,200 - $19,200 |

| 540 sq.ft. | $8,100 - $21,600 |

Dock Cost by Type

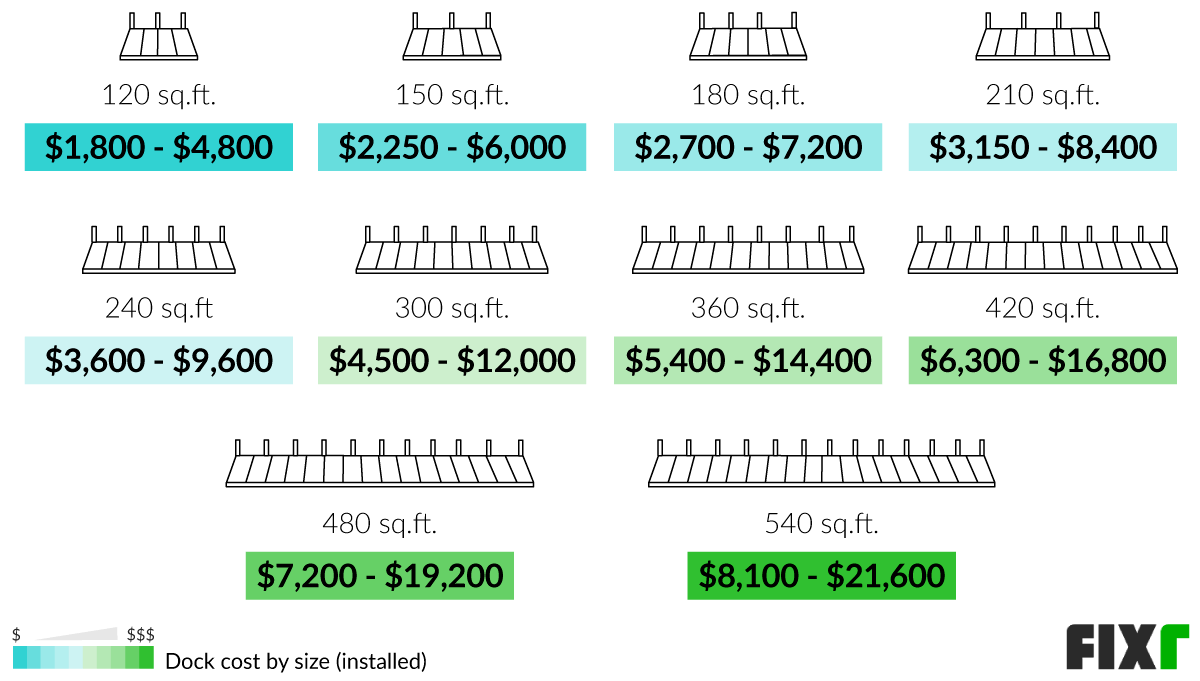

Many different types of docks are available. Some remain in the water year-round, while others are only put in at the start of the season and taken out later. Some of them use a combination of stationary and temporary portions that let you increase the size of the dock as needed. The type that you choose depends on the function you intend for it, the area it is being installed, and the aesthetics you hope to achieve. Depending on the type you can expect to pay between $15 and $100 per square foot, including installation.

| Type | Average Cost per Square Foot (Labor Included) |

| Floating | $15 - $40 |

| Piling | $20 - $40 |

| Pipe | $20 - $40 |

| Wheel-In / Roll-In | $25 - $35 |

| Crib | $30 - $50 |

| Lift-Up | $30 - $50 |

| Modular | $40 - $50 |

| Suspension | $50 - $100 |

Floating Dock

On average, the prices for a floating dock range between $15 and $40 per sq.ft., including the cost of installation. Prices vary depending on the material being used. Aluminum floating dock prices are significantly less than the cost of concrete ones. Floating docks are temporary and can be used on their own or affixed to another one. They are a great option when you are looking to extend your dock or live on a body of water that freezes over in the winter. They can easily be removed before the freeze hits, protecting them from damage.

Floating docks may also be referred to as barrel docks. They are affixed to dock float drums or specialized containers that allow the dock to float along the surface of the water. Since they float with the water, they are not as affected by sudden rises in water levels, allowing them to be used even during rainy seasons. The only drawback to them is that they move when you walk on them. You must remove them from the water each year.

Dock Piling

The cost to install dock pilings runs between $20 and $40 per sq.ft. When most people think of docks, piling docks most likely come to mind. They are sometimes referred to as stationary docks and they include wooden decking affixed to wooden pilings, which will be driven deep into the sand of the body of water to secure them. This is a permanent option and remains in the water throughout the year.

Since they are stationary, they are ideal for anglers. The availability of various configurations and decking options allows you to customize it to your liking better. Drawbacks to this type are that it can require a lot of maintenance since it is in the water all year long and requires special equipment to install. You also may have to make adjustments to it if you see a significant change in the water levels.

Pipe

Pipe docks cost about the same as piling docks running between $20 to $40 per square foot, installed. They also have a similar appearance. They use pilings to secure them to the floor of the water body. Where they differ is the form of piling and installation process. Instead of wood, they use PVC pipes filled with concrete. This makes them weighted and easier to install. Because of this, you may also hear these referred to as PVC docks.

Since they are stationary, they are good for fishing and boarding boats. You can choose from multiple configurations, allowing you to set it up to best meet your needs. A variety of deck options allows you to customize the look of the dock. The main con of this is similar to piling docks, which is that they are higher maintenance.

Wheel-In

Wheel-in docks are relatively inexpensive, running between $25 and $35 per square foot installed. Wheel-in docks are constructed from aluminum with stainless steel screws to affix the legs. The design allows for adjustment from the top without getting into the water. The ease of adjustment makes it ideal for moving it up and down when water levels change. They are designed for all water depths, from super shallow areas to areas with high depths.

They are extremely easy to install and are simply rolled into the water before being affixed into place. Once in the water, shims will be placed under the wheels to make them more stable. The aluminum material makes them durable and rust-free, meaning they will need little maintenance throughout the year. They can be placed in rocky, sandy, or firm areas, making them work in almost any type of body of water. The drawback to this type of dock is that they are not a permanent option and must be removed each year. There also may be installment issues if the slope to the water is steep.

Crib

Wooden crib docks can be one of the most expensive options, running between $30 and $50 per square foot, including installation. If you are looking for a dock type designed to last for years, a crib dock makes an aesthetically pleasing option. They are made from crates or wooden frames referred to as cribs, where they get their name. The frames are custom built and designed to be permanent.

Once you have a crib dock design and the frame constructed, it will be filled with large rocks and then finished off with decking. They are known as one of the most stable options but do not work everywhere. They extend the shoreline and disrupt the natural flow of water and possibly wildlife. Because of this, they cannot be installed in every location. You will need to check with local ordinances before beginning the construction of one of these.

Lift-Up

The installation of a lift-up dock will cost between $30 and $50 per sq.ft. They are sometimes referred to as crank up docks and use an aluminum truss design, allowing the entire frame to be lifted to keep it protected during the winter. The decking is separated into two-foot sections, affixed to a winch cable, and cranked up when it needs to be raised. They are a good option for deep water, with the ability to be placed in water up to 15 feet deep.

They are also available in multiple configurations. The most popular options are T, L, and U. They can also be designed to run parallel to the shoreline. When not being raised, the panels will be secured using locking trim strips that will make them able to hold up during harsh water conditions.

Modular

The cost of installing a module dock runs between $40 and $50 per sq.ft. Sometimes referred to as dock blocks, they are a type of floating dock designed for watersport lovers. They feature drive-on jet ski ports that allow drivers to ride up and dock them without getting off. They work by hovering just below the water and raising when the weight of the personal watercraft moves onto it.

Modular docks tend to be a more costly option requiring special decking. It needs to be durable, safe, and slip-resistant. They are beneficial due to their function and stability but can be high maintenance. They are also designed to be aesthetically pleasing and can be customized to fit your desired configuration.

Suspension

This type of dock is one of the most expensive, running between $50 and $100 per sq.ft., with installation. They may remind you of a traffic bridge because they use cables to hold them over the water instead of a supporting foundation on the bottom. This provides them with the benefit of allowing water to flow freely beneath them.

They are sturdy and durable, making them able to withstand harsh winters without being removed. Since they are not fastened to the ground under the water, they can be raised or lowered to accommodate water level changes. The primary drawbacks are that they are extremely high maintenance and expensive.

Suspension docks can be articulating or cantilevered docks. Articulating docks are designed to be raised to prevent ice damage. They can be designed in a U shape with a boat lift to raise both the boat and dock out of the water for the winter. A cantilevered dock is an alternative to an articulating one and uses a counterbalance system to raise it out of the water. Both types are ideal for dealing with a sensitive ecosystem.

Dock Decking Cost by Material

The cost to install a dock depends largely on the type of decking you choose for the surface. Decking costs range from low-end wood options to more expensive but extremely durable options, such as concrete. On average, a homeowner can expect to pay $40 per sq.ft. for decking. When choosing which type of decking you want, consider how long you want it to last and the aesthetic appearance you desire. Below are some common boat deck prices based on the cost per square foot with labor included, ranging from $15 to $500.

| Material | Cost per Sq.Ft. (Labor Included) |

| Pine | $15 - $50 |

| Plastic | $15 - $60 |

| Cedar | $20 - $60 |

| Vinyl | $20 - $70 |

| Pressure Treated | $20 - $70 |

| Aluminum | $25 - $75 |

| Hardwood | $30 - $90 |

| Synthetic Wood | $90 - $175 |

| Concrete | $200 - $500 |

Pine

For pine decking material, you can expect to pay $15 to $50 per sq.ft. Pine wood is one of the most common types of softwood used for dock decking. It is popular because it is one of the most affordable and lasts up to 20 years if maintained. But the required maintenance is a drawback for some because it needs to be done annually. This includes applying a water sealer to prevent water saturation. Another drawback is it can splinter over time, requiring sanding or plank replacement.

Plastic

The cost for plastic decking materials runs between $15 to $60 per sq.ft. Plastic docking is often chosen because it is a low-maintenance option. It is often made out of polypropylene, polyethylene, polyvinyl chloride, or a combination. The boards are lighter than other options and have a shiny appearance. Since no organic materials are used, it is less likely to grow mold and mildew than wooden docks. And while it is a lower maintenance material, one of the best ways to ensure its lifespan is to take care of it. This includes washing it regularly with a power washer and scrubbing it with cleaners. And if properly taken care of, plastic docks can last at least 30 years and withstand inclement weather. The main con to this option is that it can become hot to the touch on sunny days.

Cedar

Cedar decking is relatively inexpensive, costing $20 to $60 per sq.ft. Cedar decking is another popular softwood dock option that is considered an upgraded option from pine. It is rot-resistant and designed to last 25 years or more if properly treated. It stays cool in hot temperatures and can be stained to customize the look. One of the drawbacks homeowners experience with cedar decking is that it requires annual waterproofing and can splinter. It tends to be knotty, which may damage the aesthetic appeal.

Vinyl

The cost per square foot for vinyl decking installation ranges from $20 to $70 per sq.ft. A high-impact, weather-resistant compound is used to create vinyl decking. This product is similar to vinyl siding but has been tested for use as dock decking material. The formula includes ultraviolet inhibitors, making it resistant to fading when exposed to sunlight. This type of decking is resistant to flaking, peeling, and corrosion. Other benefits include that it is durable, slip-resistant, easy-to-clean, and will never need to be painted. These features make it a low-maintenance option. Since vinyl is such a durable material, expect your dock to last at least 25 years.

Pressure Treated Wood

Pressure-treated wood runs from $20 to $70 per sq.ft. Pressure-treated lumber is often used for docks. This treatment makes it more resistant to rotting, fungus, and bugs. Pressure-treated wood is an affordable option and produces an aesthetically pleasing dock. There are some cons to this option, though. Over time, this type of material cracks, warps, or splits, requiring replacement. Additionally, it requires annual maintenance, such as applying a wood preservative and staining to help it last longer. With annual maintenance, pressure treated wood docks last up to 20 years or more on average.

Aluminum Dock

Aluminum dock cost for decking runs $25 to $75 per sq.ft. For homeowners looking for decking that requires no maintenance, this is the best option. They will not warp, rot, or decay and are durable enough to stand up to years of use. Aluminum decking can be powder coated and painted, allowing you to customize its look. You can even choose options painted to look like real wood. It tends to get hotter than wood decking but is still comfortable to the touch. One of the most appealing aspects of owning an aluminum dock is its lifespan, ranging from 30 to 50 years.

Hardwood

The main drawback to this form of decking is the cost, which runs $30 to $90 per sq.ft. Exotic hardwoods are often chosen for dock decking options due to their aesthetically pleasing look. Some common options include Tigerwood, Garapa, and Ipe. These hardwoods resist rot, mold, and wood-boring insects. They do not deteriorate like softer wood options and do not retain heat like synthetic options. They are also low maintenance and made for longevity, with some varieties lasting up to 75 years.

Synthetic Wood

This type of decking can be a more costly option, running $90 to $175 per sq.ft. Synthetic decking is made from products that contain PVC. It can be created with solid PVC or wrapped in it. They require no regular maintenance and are designed to last for many years. Even though they are synthetic, they provide similar aesthetics to wood docks because they are designed with natural wood details. On average, synthetic wood docks last up to 20 years or more, making them an incredibly durable choice.

Concrete

The cost of concrete for this type of dock runs between $200 and $500 per sq.ft. They are one of the most expensive options but are often chosen because they are designed to last for decades. They are free-floating and placed on top of joists to hold them in place. You can have it painted in various colors to gain the aesthetics you are looking for, and it requires no regular maintenance. The primary drawback besides the cost is that it came to become very hot to the touch when in the sun for long periods.

Labor Cost to Build a Dock

Labor is a large portion of the dock building costs. In most cases, installation costs around $30 per sq.ft., making a 6 x 30-foot dock cost approximately $5,400. However, the cost varies depending on the type of dock and materials used. Labor rates can run as high as $50 an hour. Higher rates are charged in states with a higher cost of living. With labor and materials, the total dock construction cost average is around $15,000.

Without considering the cost of labor, boat dock prices range from $4 to $35 per sq.ft., depending on the material used. However, building with concrete is significantly more expensive, with the dock cost per sq.ft. ranging from $50 to $300. If you need to run electrical wiring for mooring or lifting, this costs $6 to $8 per linear foot, with most electricians charging a minimum of $200.

The installation of a dock varies tremendously depending on the type. A typical piling dock begins with a CAD drawing to determine the size, shape, and load. Next, the water and waterbed are inspected to make sure they can handle the type being considered. The area where the pilings will go is marked. They are driven deep into the sand beneath the water. This is done with a large machine that pounds the wood until it reaches the correct depth.

Once the pilings are sunk, the rest of the installation is a lot like a deck. A frame is built over the pilings, and the decking material is laid on top. This takes several days to four weeks to complete from start to finish depending on the deck’s size, the materials, and how deep the pilings must be sunk.

Since dock installation varies in complexity and requires professional equipment, it is always best to use a professional installer. Safety is also a top concern with docks. A professional builder or installer knows the requirements that ensure it is safe and operational.

Dock Replacement Cost

For a complete dock replacement, you will be charged both the installation and removal costs. This cost depends on the dock removal cost and how much of the frame or substructure needs to be replaced. Replacing the old decking runs $4 to $300 per sq.ft., depending on its size. In some cases, you may be able to replace the decking alone if there is damaged or rotted wood.

Other costs associated with replacement involve the other components related to the dock. If the floats on a floating dock need to be replaced, you can expect to pay between $150 and $200. Repairs to frames cost between $150 and $500. New bumpers could add between $8 and $30 per sq.ft. Replacing pilings and pipes can be one of the most costly expenses running $300 to $1,600 per piece.

If you are completely removing your dock and reinstalling a different one, you can expect to pay the removal cost of between $250 and $1,000, plus the cost of the new type chosen, which can average $15,000.

Location

Docks can be installed on any body of water if allowed by the municipality. The cost to install docks will be the same in almost any location. However, there are a few things to consider, depending on the location of the installation. The most common bodies of water to install docks are ponds, rivers, and lakes. Each location will present its challenges and may be better for certain docks.

Pond

Ponds tend to be shallower, making installation an easier process and allowing you to choose from a wider range of options. A couple of popular options for ponds are piling docks and pipe docks because they offer many configurations. Typically pond docks will be used for swimming, fishing, and shallow-bottomed boats. You may prefer L, T, or H configurations for these activities. Although they can be pricey, some homeowners choose a suspension dock if their pond has a more fragile ecosystem.

River

Installing a dock on a river presents several unique challenges, depending on the depth of the river, the type of river bottom, and the flow of the water. River bottoms tend to be rockier, making piling docks more difficult and expensive to install. In this instance, a floating dock may be the better option. They can be the best option with faster flowing water because they move with it. Crib docks are not advisable in these areas because their installation disrupts the flow of water.

Lake

One of the most common places to install a dock is on a lake. This is because lakes are often popular for boating, swimming, and other types of water activities. The cost of building a dock on a lake will be determined by the type and configuration of the chosen dock. If the water level is deep where you plan to install it, a piling dock would be more advisable than a crib one due to the type of installation required. But a floating one would be preferable to a piling dock if the bottom of the lake is more rocky than sandy.

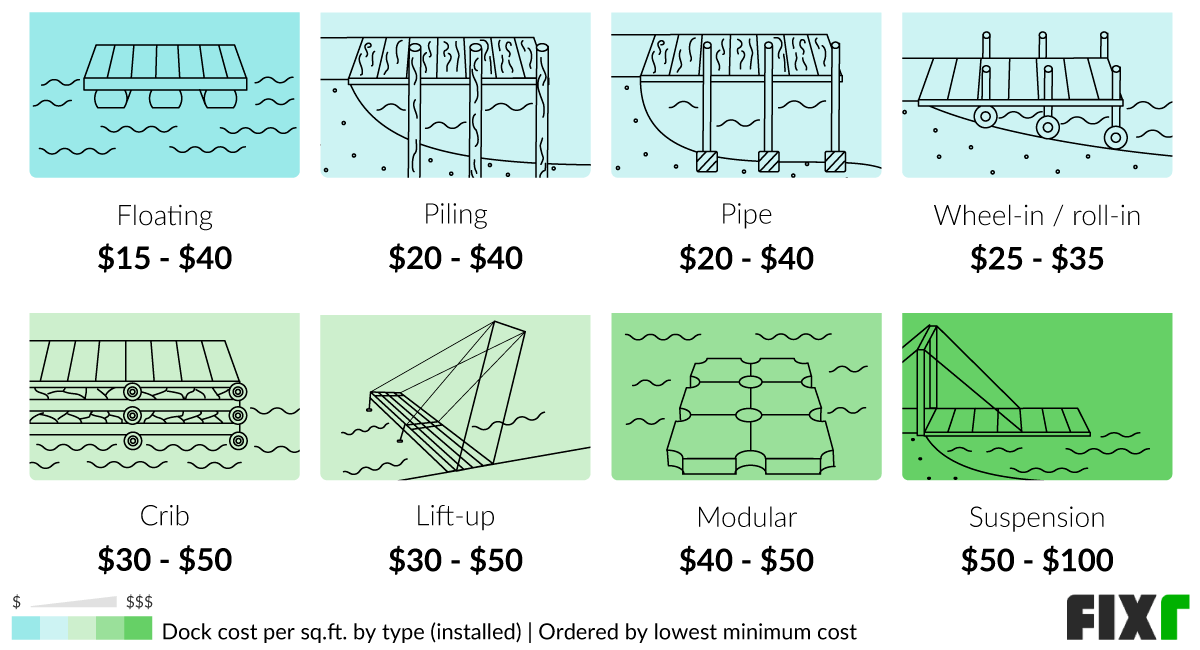

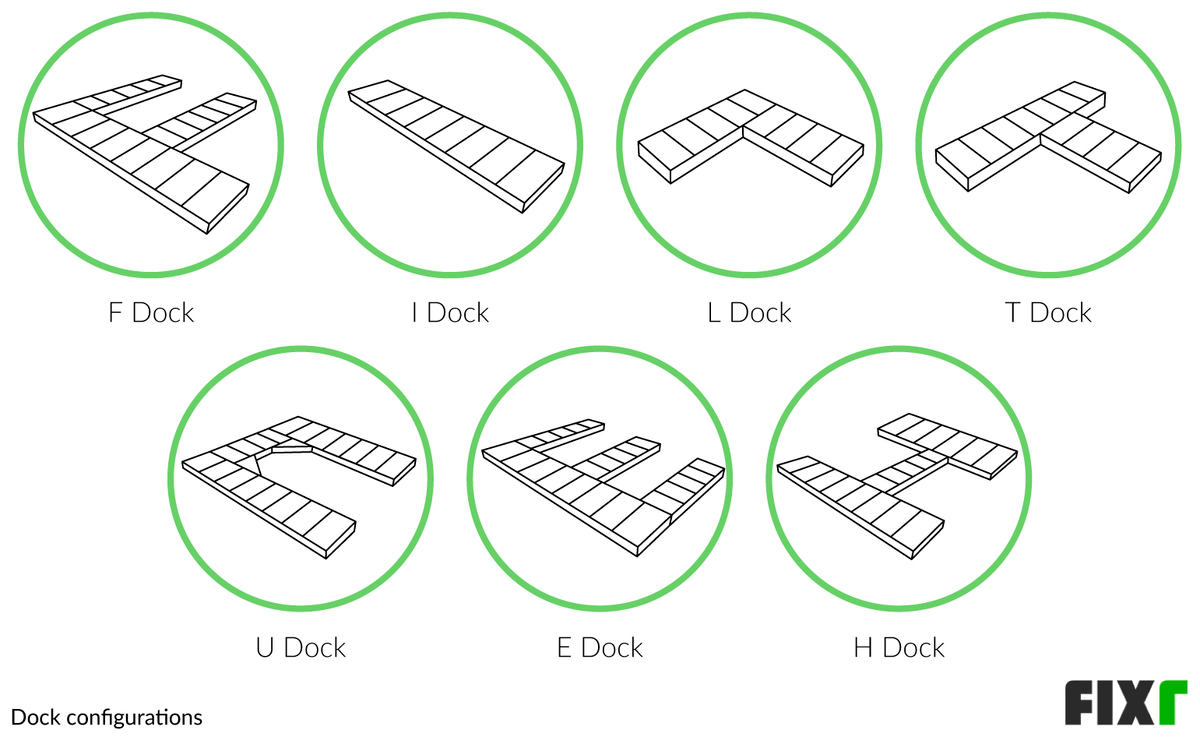

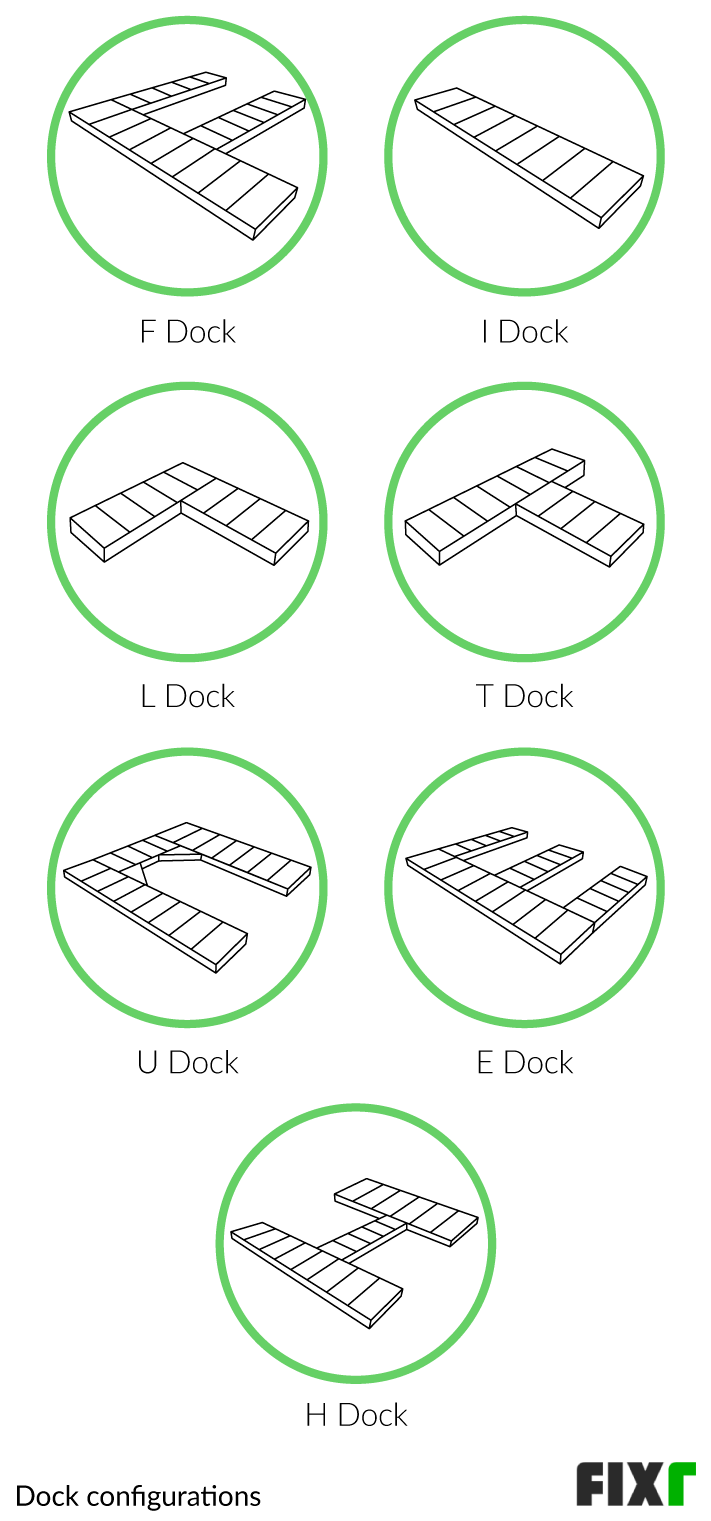

Configuration

The most common configuration for docks is to have the main portion extending straight out over the water, but this is not the only option. In some cases, a narrow walkway can widen into a larger dock, only to narrow again at the boat slip.

In other cases, if you have multiple boats, it may be beneficial to configure the dock in an F, I, L, T, U, E, or H shape so that you can attach boat slips at various spaces. Other configurations may include a patio at one end or a Harbor-style dock with a walkway running parallel to the water and extending the arms outward. The key to determining the best configuration is to figure out how you intend to use it. Fishing, sunbathing, and entertaining may need a wider section, while a dock meant solely for accessing a single boat can be a narrow walkway.

F Shape

F docks are distinctive by their two parallel extensions coming off the main part of the dock, forming the F shape. This configuration is most often used when docking a small personal watercraft between the two parallel extensions, allowing access from either side. They can be ideal when there are two watercraft, one on each side of the parallel extensions.

I Shape

I docks are the most common type of configuration and involve one simple straight extension out into the water. They can be ideal when one or more large boats are needed for docking. The large boat can simply lay to one or both sides on a shore station. Homeowners also choose this configuration when looking for the least costly and most simple installation option.

L Shape

L docks are ideal for fishing, swimming, and sunbathing. They make a distinctive upside-down L shape, with one vertical piece and a horizontal decking piece, a horizontal piece that connects. The decking parallel to the shoreline creates ample space to set up chairs for fishing or for lounging while allowing you to enjoy the view of the water.

T Shape

The T dock configuration works well as a fishing and swimming dock. It provides the added benefit of creating protected areas on both sides of the dock. These areas can be great for young children to swim. If the T configuration is used for personal watercraft, you will have space on each side to dock multiple ones. The T dock will have one extended dock straight from the shoreline, with decking parallel to the shoreline connected at the top.

U Shape

The U dock is an excellent shape for homeowners with multiple boats. This unique shape gives individuals the opportunity to store up to three boats on their dock securely while allowing room for swimming. The middle of the U is most beneficial for smaller boats, such as fishing boats, kayaks, and canoes. The outsides of it are ideal for housing recreational boats while providing entry points into the water for swimming.

E Shape

Similar to F docks, E docks have distinct parallel extensions that come off its main body. The main difference between an E dock and an F dock is that the former has an additional extension, creating even more storage options for boats and recreational water vehicles. The middle of the extensions is ideal for housing smaller boats, such as kayaks, canoes, and fishing boats. The outer extensions are ideal for housing larger boats, such as speed boats, jet skis, and pontoon boats.

H Shape

H docks are distinctive by having two primary docks connected in the center by a perpendicular middle piece. They are a good option if you use it for multiple functions at one time, as it provides ample space apart from each other. It allows you space to dock one or more watercraft while also having a separate space to enjoy fishing.

Double-Decker Boat Dock

You can expect to spend between $15,000 and $50,000 for a double-decker boat dock, with the average running around $30,000. A customized option when you are looking to create a space to store your boat and for entertaining, a double-decker boat dock might be a good option. These docks feature a main dock, water level that allows you to board and deboard a boat easily. An overhead deck is constructed above where the boat will dock, creating a living and entertainment space. The upper deck provides some basic protection for the boat when inclement weather occurs. Since they require extensive planning, design, and labor, they are significantly more expensive than other options. It is generally built in stages, starting with the bottom deck. Once the bottom’s structure is sound, the second level is built. And because of the scope of the project, a double-decker boat dock typically takes multiple days to complete. Double-decker boat docks vary greatly in project scale and size. The most popular materials are aluminum upper docks framed with galvanized steel frames, giving the structure stability and durability. Other common materials are synthetic wood, cedar, pine, and concrete.

Benefits

Docks are not for everyone. Not only do you need to have direct access to a body of water, but you also need to make use of that access for it to be truly needed. If you swim regularly, entertain, or have a boat you want to be moored for easy access, it can be very beneficial. Having a dock allows you to fish, barbecue, swim, and boat easily.

However, even if you regularly use one, it requires a lot of maintenance to stay in good condition. If yours is stationary, you need to check it for wood rot, even below the water level. You also need to replace the decking and stain periodically and scrape it regularly.

Docks can sometimes become a liability. If you have people entering your yard and using your deck without permission, you may be liable for accidents unless you gate the entrance. They may also attract nuisance birds and wildlife such as ducks, loons, and herons that may soil the decking.

Moveable docks must be put in and taken out of the water each year and cleaned and inspected. This amounts to a lot of work, even if you do not use it frequently.

Requirements

When it comes to docking building requirements, the greatest determining factors are the size of the dock and the location of where it is being built. In many states, there are very few restrictions when it comes to building a dock, as long as a permit has been secured and building regulations have been met. In some areas, no area of the dock can be wider than 8’ wide. And in many locations, they cannot extend further than 1/4th the width of the body of water. These restrictions are more pronounced in areas with extremely high boat traffic or if the lake is located in an urban area. If you live in an HOA, there may be additional restrictions and requirements that need to be considered before building your dock.

Maintenance

The maintenance that your dock needs varies tremendously based on things like the climate, type of water, type of docking material, and how much use it gets.

At a minimum, you should inspect the dock at the end of each season. Keep it clean, and make any necessary repairs to worn, cracked, or broken areas. If yours is moveable, removing it from the water at the end of each season helps extend its life. Docks with wood decking require regular annual maintenance to extend their life. This can include staining, oiling, and providing a protective water sealant. Warped or damaged boards should also be watched and replaced.

Deck vs Dock

While docks and decks both include decking and can be linked to entertainment and recreation, their location and primary functions differ. Docks are placed along the water, starting at the shoreline and extending outward. They are used to make it easier to get into the water, as a place to fish, or to make it easier to get on and off various watercraft. While the average dock costs $7,000 to $25,000, a deck costs between $5,000 and $15,000 on average.

Decks can be placed along the shoreline or extended further into the water. They can be attached to your home to create an additional outdoor living or entertaining space. Decks range in design, size, and functions. Smaller versions may simply be used as a place to relax and get some sun, while others may be large enough to accommodate an entire outdoor living area.

| Project | Average Cost (Labor Included) |

| Deck | $5,000 - $15,000 |

| Dock | $7,000 - $25,000 |

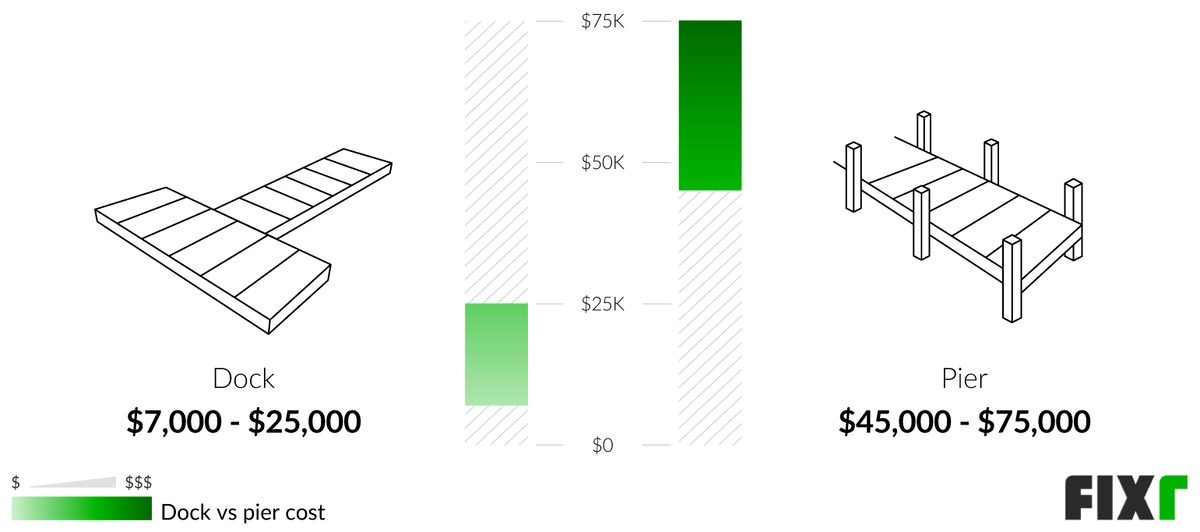

Dock vs Pier

The main difference between a dock and a pier is their function. Simply put, a dock acts more as a parking space while a pier functions more as a sidewalk. Piers are not designed to dock boats but as a transitional structure between water and land. Piers are often made of concrete or steel. Piers can often be constructed to allow homeowners to travel between the shore and a boat dock farther across the water. The cost to build a pier runs between $45,000 and $75,000. Below, you will see the cost comparison between a dock and a pier.

| Project | Average Cost (Labor Included) |

| Dock | $7,000 - $25,000 |

| Pier | $45,000 - $75,000 |

Boat Slip vs Dock

There are many similarities between a boat slip and a dock. For certain types of docks, a boat slip acts as a single parking spot for your boat rather than a whole dock. Boat slips can be incredibly beneficial for smaller boats, such as fishing boats, small sailboats, and kayaks. Boat slips can either be part of an existing dock you are building or connected to larger docks in a marina. To simplify, a dock is a structure, while a boat slip is like the parking space for the boat. Boat slips range from 25’ to 50’ feet in length. In total, expect a boat slip to cost between $1,000 and $5,000. The cost of a dock runs from $7,000 to $25,000.

| Project | Average Cost (Labor Included) |

| Boat Slip | $1,000 - $5,000 |

| Dock | $7,000 - $25,000 |

Enhancement and Improvement Costs

Boathouse

Many boat docks have additional structures nearby, including boathouses. Digging a foundation for these structures costs an additional $9 per sq.ft. If you choose to build a boathouse in addition to your dock, this adds between $15,000 and $20,000 to the cost.

Covered Boat Dock

Some docks used year-round may benefit from having a covered section to keep the sun and rain off the boat. Typically, covered docks can be built of the same materials as the rest of the dock, although aluminum docks usually have a stretched canvas top. Covered boat docks start at an additional $12,000 for a wooden dock, which on average costs $19,500 to $39,700.

Boat Lift

Homeowners considering adding a boat lift should expect to pay $2,000 to $20,000, with an average price of $8,000. Often considered a worthwhile enhancement, a boat lift helps you make more use of your boat and may even replace a traditional dock. Boat lifts are designed to raise and lower your boat into the water, helping passengers get into and out of them. They can also keep your boat from floating away, especially when the water level gets high. These lifts can be used to pull your boat out of the water during colder water when it will not be in use.

Lighting

If you choose to have lighting installed, you can expect to pay an electrician $40 to $100 per hour for at least three to four hours of work. That said, there are many benefits to adding lighting to your boat dock. It creates the perfect finishing touch and can be beneficial for aesthetic reasons. It also provides a way to let watercraft out at night easily view the area that your dock encompasses. A variety of types of lighting are available to choose from. Underwater lights are a great way to illuminate your whole dock. Motion-activated floodlights save power but illuminate the area when needed. Piling lights provide some ambiance without being too harsh on the eyes. LED bumper lights create a unique appearance.

Dock Ladder

A very useful tool for swimmers, dock ladders cost between $200 and $800. If you use your dock to get in and out of the water for swimming or tubing, then a ladder is a must. They make it safer to enter and exit the water and lower the risk of injury. While most ladder options are created with aluminum, you can opt for wooden designs. All the ladders use special hardware to secure the ladder to the dock making it more stable.

Dock Ramp

Considered beneficial for many reasons, dock ramps cost between $1,200 and $4,500 to have one installed. If you plan to move your watercraft in and out of the water regularly, then a ramp may be worth adding. They are designed for launching boats and allow you to back the boat easily into the water using your vehicle. You can also have smaller ramps installed for use with personal watercraft to get it in and out of the water easily.

Dock Bumper

The cost of dock bumpers varies with the size, but they cost $80 to $175 each. They are installed along the sides of the dock. They are placed there to protect both the dock and the boat if the boat hits it during the docking process. If your boat were to hit one gently, it would slightly bounce back without causing any damage.

Dock Mooring Whips

Designed to protect boats in areas where the wake is rough, mooring whips cost between $250 and $600, depending on the brand choice and size needed for your boat. They look like fishing poles that are affixed to certain angles, tensioned, and then arched downward to hook your boat when it comes in. The tension keeps your boat a safe distance from the dock. This protects your boat’s finish and prevents dock rash from occurring.

Additional Considerations and Costs

- Permits. You need a permit to build a dock. Most of them have regulations they must follow, particularly in sensitive areas, regarding the size, shape, and material. You must submit plans before proceeding.

- Winter. In areas where the water freezes during the winter, some docks may be damaged by the freeze-thaw cycle. This includes some plastics and pipe dock. Include a winter plan to ensure that your deck winters well.

- Regulations. If you choose a wooden dock, check local regulations before proceeding. Some chemicals used in pressure-treated wood cannot be introduced to freshwater.

- Property value. If you have a house on the water, a dock can increase the value of the property because it provides greater access to the water. The amount varies from state to state and by the type.

- Prefab. If you are looking for an easy-to-maintain option with less installation time that can be removed at the end of the season, a prefabricated dock may be the best choice. They are pre-built and made directly in a factory, without customization for size, materials, etc. The most common types of prefab docks are floating, wheel-in, and modular. These typically run between $1,000 and $3,000.

- Seawall. If you have been losing land due to wave encroachment, a seawall can help prevent further damage and protect your dock from wave damage or damage from rapidly rising water levels. Seawalls run between $150 and $800 per linear foot.

- Inspections. Like many structures, it is recommended you have your dock inspected periodically to ensure its structural integrity. In climates with inclement weather, they can be damaged. How often you have it inspected depends on the area you live in since they are more vulnerable in certain climates. Other factors that determine the frequency of your inspections include the material, its age, and whether or not you plan on selling your home in the near future. On average, inspections cost between $50 and $100.

- Terrain. Certain obstacles increase the final installation price. Conditions such as rough, uneven terrain, extremely fast current, extreme depth variations, etc. This is due to increased labor and material costs.

- Soil. Pilings for dock installation need to be installed at least 6 to 8 feet. If soil conditions pose an extreme challenge for installing these pilings, installation costs will increase. Also, docks built on extreme slopes are more likely to experience erosion, decreasing their lifespan. Leveling out the slope or adding a seawall slows down erosion but adds cost.

FAQs

- Does adding a dock increase home value?

In many cases, yes. Boat docks, especially on lakefront property, add significant value to your property. They are considered an enhancement to the property, similar to a swimming pool or a hot tub. They also add enjoyment to the property, increasing the property’s value.

- Do you need permission to build a dock?

That depends on many factors. In many states, the DNR does not require permission for you to install a dock on your lakefront property. In many cases, all that is needed is a permit to build a dock. If you live in an HOA, however, you need permission from your HOA before building it.

- How far out can I build my dock?

This depends on a few factors. In many areas, the length cannot exceed 1/4th of the width of the body of water where you are installing your dock. Depending on where you live, the size of your dock needs to comply with local ordinances, so check with your state’s regulations before installing one.

- How much does a boat dock cost?

There is a wide range of costs for boat docks. The price depends on many factors, including the size, materials, and shape. On average, they cost around $15,000, with prices typically ranging from $7,000 to $25,000.

- What is the best wood to use for a dock?

If you use the dock in freshwater, pressure-treated wood to .60 pcf is necessary. Cypress, cedar, and Douglas fir are good choices.

- How long does it take to build a dock?

The time depends on the type and size of dock. Some can be built in a day, while others may require a week or more.

- How much does a covered dock cost?

Because covered docks require more labor and materials than uncovered ones, the cost of building a covered dock will be higher. Expect to pay a minimum of $12,000 for a covered dock.

- How much does it cost to repair a dock?

Dock repairs vary tremendously depending on the material and where the repair is needed. For example, a wooden dock is generally cheaper to repair than an aluminum or a concrete deck since the materials are cheaper. Expect to pay anywhere from $3 to $250 per sq.ft. for repairs depending on the material.

- What is the difference between a deck and a dock?

Deck and docks have many similarities and differences. They use many of the same materials, but their main differences lie in their structural purposes. A deck is a structure used on land. A dock is a similar structure meant for use on the water. This means they will have different structural supports to ensure their durability.