Updated: January 31, 2025

Written by Adam Graham

Cristina is a home remodeling and design specialist with more than 5 years of experience in the industry. As a former member of the Fixr.com editorial team, she collaborated with industry experts to deliver accurate and reliable information on trends, news, and advice for homeowners and professionals. Her work has been featured in major publications including Forbes, Realtor.com, and the official publication of the National Kitchen & Bathroom Association.

Learn moreReviewed by Cristina Miguelez

Tile floors are beautiful, versatile, durable, and available in patterns, colors, and materials to complement any home. Tile floors have been in use for centuries and continue to offer many of the same benefits, including beauty, style, and low-maintenance flooring that lasts. Many materials can be used to create tile floors. These range from man-made to natural materials, in a wide range of colors, shapes, and sizes.

This means that there is a wide range of costs associated with floor tile installation. The national average range is between $1,000 and $5,000, with most people paying around $3,500 for 200 sq.ft. of 12-inch porcelain tile installed. The low cost for this project is $500 for a 50 sq.ft. bathroom floor of ceramic retro tile installed, while the high cost is around $11,520 for 200 sq.ft. of onyx marble tile sealed and installed.

Tile Flooring Installation Cost

| Tile Flooring Prices | |

| National average cost | $3,500 |

| Average range | $1,000-$5,000 |

| Low-end | $500 |

| High-end | $11,520 |

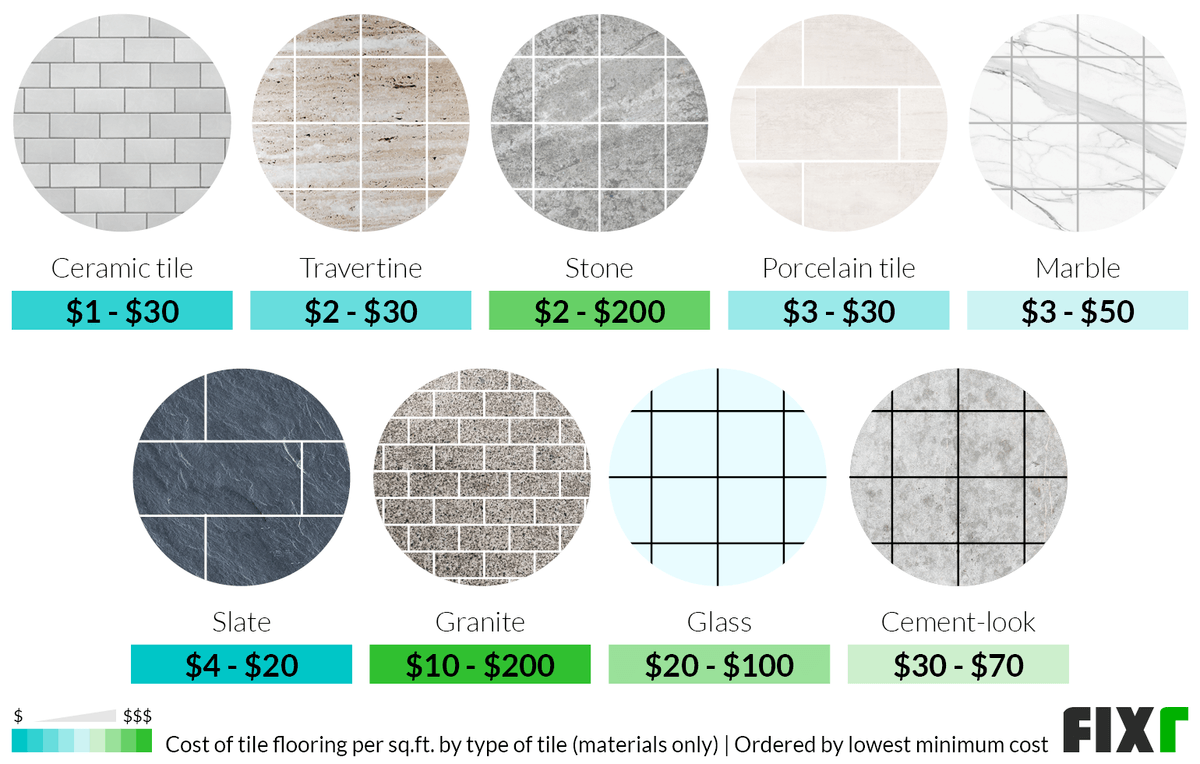

Tile Flooring Cost by Type of Tile

Tile comes in a wide range of different materials. Each material also comes in many subtypes, including finish, color, shape, and size. The materials can be natural or man-made, precisely cut or approximated, and they all have their own characteristics and level of durability and care. They also have varying cost ranges to consider:

| Tile Type | Tile Cost per Sq.Ft. (Material Only) |

| Ceramic Tile | $1 - $30 |

| Travertine | $2 - $30 |

| Stone | $2 - $200 |

| Porcelain Tile | $3 - $30 |

| Marble | $3 - $50 |

| Slate | $4 - $20 |

| Granite | $10 - $200 |

| Glass | $20 - $100 |

| Cement-Look | $30 - $70 |

Ceramic Tile Floor

Ceramic tile for floors averages from $1 to $30 a square foot. Ceramic tile is a man-made material crafted from clay. The material is fired either once or twice and is given a glaze that can be glossy or matte. Typically, floor tiles have a matte glaze and/or a textured surface. Most ceramic tiles with a glossy glaze are not rated for floor use. Ceramic floor tiles can be mosaics up to large-format tiles 16 inches in size. They come in many different colors and styles as well.

Travertine Floor

Travertine tile costs between $2 and $30 a square foot on average. Travertine is a unique stone similar to limestone in composition. It was formed inside hot springs, and escaping water vapor left small tunnels in the stone. This can lead to holes in the surface of the tile or in visible lines in cross-cut travertine. The holes need to be filled, either before installation with epoxy or during installation with grout. Leaving the holes unfilled means that the tile is more susceptible to damage long term. Like all stones, travertine should be sealed before grouting.

Stone Tile Floor

Stone tiles for flooring average $2 to $200 a square foot, depending on the type and material. There are many types of stone tile, including travertine, slate, granite, and marble. They can all be used on the floor, but the way they look and perform long term differ. Most types of stone require sealing during installation and on an ongoing basis. Some may be more durable and better suited to flooring than others. Some types of stone are more likely to stain, like white marble, while some are very easy to care for like slate. With the range of different materials in this category comes a wide range of costs, installation methods, and care.

Porcelain Tile Floor

Porcelain tile for flooring costs between $3 and $30 a square foot on average. Like ceramic tile, porcelain is a man-made material crafted from clay. Unlike ceramic tile, porcelain is made of clay dust that has been tightly compacted, then fired to extreme temperatures. Porcelain may be glazed, but it does not need to be. In most cases, the color goes right through the material. Porcelain is incredibly durable, resists cracking and chipping, and does not require any special care. It comes in a wide range of sizes and styles.

Marble Tile Floor

Marble floor tiles range from $3 to $50 a square foot on average. Marble is a metamorphic stone made mostly of calcite. It comes in a wide range of colors and styles and can be cut and shaped into different sizes. Marble can be ground to a high polish, left matte, or tumbled for a more rustic appearance. It requires sealing during installation and on an ongoing basis. Marble is susceptible to staining, etching, and in the case of white marble, stunning or bruising when used on the floor.

Slate Tile Floor

Slate tiles cost between $4 and $20 a square foot. There are two different types of slate tiles - gauged and ungauged. Gauged tiles have been cut to be uniform in shape and size. Ungauged tiles are roughly sorted into the same shape and size and may vary in thickness from piece to piece and within one piece. Ungauged tiles are much less expensive than gauged, but they cost significantly more to install than gauged tiles. Both types of slate come in an range of different colors and textures.

Granite Floor Tiles

Granite tile for flooring ranges from $10 to $200 a square foot. Granite is not used as frequently on floors as other types of stone, but it is available in a wide range of different colors in tile form. Most granite tiles are 12-inch squares and polished. However, some granites like Black Absolute are available honed and in other finishes. Some popular granites are also available in large-format tiles. Granite is an igneous rock made mostly of silica, feldspar, and quartz. Of the various stone flooring types, it tends to be among the most durable.

Glass Floor

Glass tile for floor use costs between $20 and $100 a square foot on average. Not all glass tile is suitable for use on the floor. Most types of glass that can be used in flooring are mosaic, meaning 2-inches in size or smaller. Some larger glass tiles can be used on the floor, but they may contain other materials to strengthen them. Therefore, they may not be translucent, transparent, or iridescent the way that glass wall tiles and glass mosaic tiles are. Glass tiles require very precise installation. Once installed, they are very easy to clean and care for and require no special sealers or other materials.

Cement Floor Tiles

Cement-like floor tiles average $30 to $70 a square foot. Cement is the main ingredient in concrete and is not a hard or durable material on its own. If you want the look of cement or concrete tiles, it is possible to get it with cement-like or concrete-like porcelain tile flooring. This is a special porcelain type that comes in large-format tiles. It has a glaze and finish that make the tiles look like polished concrete. Like all porcelain, the cement-like tiles are very durable, low maintenance, and easy to care for.

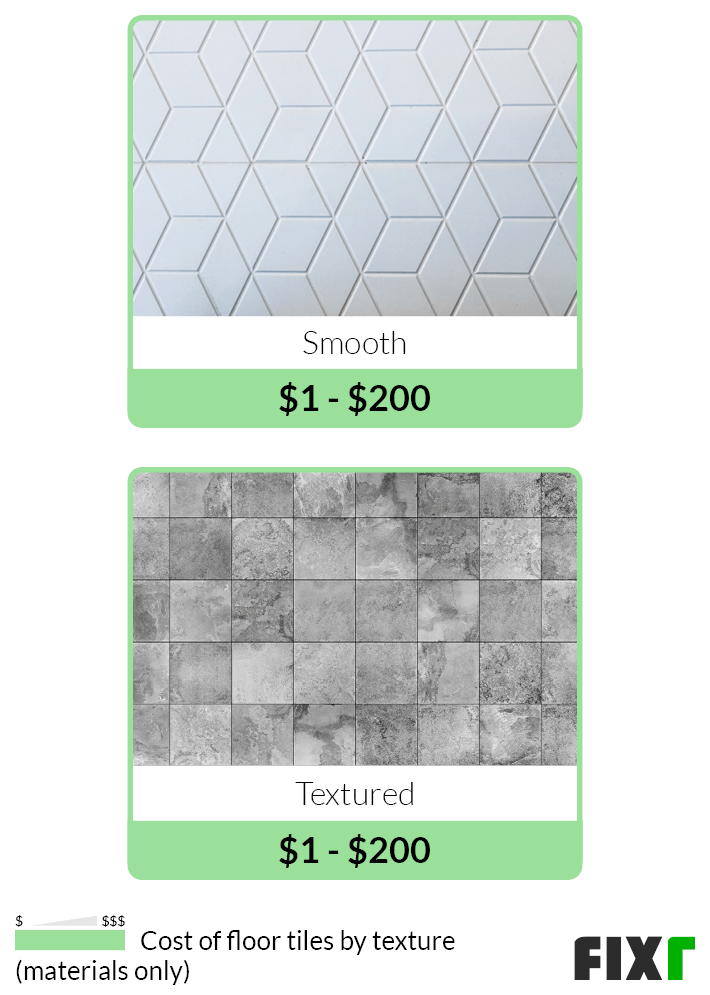

Floor Tiles Price by Texture

In addition to the tile color, size, and material, you may also want to consider its surface texture. While every tile type has its own subtleties in the finish, it is possible to find both smooth and textured tiles in nearly every material, from glass and stone to ceramic. Costs are not necessarily impacted by the surface texture, but care, use, and appearance are:

| Texture | Average Cost (Material Only) |

| Smooth | $1 - $200 |

| Textured | $1 - $200 |

Smooth Tile Floor

Smooth floor tiles can be found in every type of material, with costs ranging from $1 to $200. A smooth tile floor may have a matte or polished finish. Both matte and glossy tiles make excellent floor tiles. It is simply a matter of taste which you prefer.

Depending on the tile, smooth tiles may also be slick underfoot. For example, glazed and polished porcelain can be slippery when wet. Polished marble, due to the porous surface texture, is not slippery. If you are concerned about a slick floor, choose a smaller tile. Smaller tiles have more grout lines, and the grout lines increase the texture of the floor. You can also apply an impregnating, silicone sealer to the surface of any tile to increase its slip resistance so that you have a smooth tile floor without worrying about slipping.

Smooth tile floors are easier to care for than textured. They can be easily swept, mopped, and in some cases, vacuumed without issue. Smooth tiles made of any stone should be sealed to protect them from stains.

Textured Tile Floor

Textured floor tiles can also be made of any material and cost between $1 and $200, depending on the material and tile. Textured tiles can be created in many different ways. Porcelain and ceramic are usually textured directly into the clay, but the glaze can also be built up to give it texture. Some porcelain tiles are made to look like fabric and have layers and layers of built-up glaze that creates a unique texture underfoot. Stone tiles can be given texture by tumbling, chiseling, or flaming the stone to remove weaker particles from the surface. Ungauged slate is always textured because the material will cleft and split along its layers in unique ways.

Textured tiles increase the slip resistance of the floor. They are harder to keep clean, however. They often trap and build up dust and debris more easily than smooth textured floors. And, textured stone tiles require the same sealing that smooth tiles require. Take care with textured glass tiles on the floor because they sometimes have sharp corners that stick up above the rest, which may cut bare feet.

Tile Patterns for Floors

One of the best things about a tile floor is the ability to lay the tiles in many different patterns. Mosaic tiles can be purchased in patterned sheets that are laid together to create one overall pattern across the floor. Larger tiles of varying sizes can be combined to create different patterns as well.

Any pattern that you choose other than straight set rows of tile increases the costs of your project by 10% to 20%. This includes an additional 10% to 20% of materials needed for cuts and the additional labor required to lay the tiles in the pattern of your choice. You can use any size tile for the following patterns and any material you choose. It is also possible to combine materials and colors within each pattern for a unique installation.

Straight Set Floor Tile Patterns

A straight set pattern is simply square or rectangular tiles set in straight rows. The tiles are stacked on top of one another with no variation. This is a good pattern for rooms of any size that are fairly proportional. This pattern does not work as well in long, thin spaces because it tends to emphasize them. Any size tile works in this pattern, regardless of the room size. Using larger tiles in this pattern eliminates grout joints and makes the space seem larger.

Diagonal Floor Tile Patterns

A diagonal pattern is simply a square tile turned on its side at a 45-degree angle. This is a good pattern for long, thin rooms and hallways. It forces the eye out to the corners of the room, which visually widens it. Because each tile around the perimeter of the room requires a cut, you need extra tile to complete the pattern. This is a good pattern for mixing two or more colors because you can accent different rows and create various color patterns within the layout.

Running Bond Floor Tile Pattern

The running bond pattern is most often associated with subway tile, but it can be used with square tiles as well. This is an offset tile pattern where each row starts a half tile into the next. This pattern works in rooms of every shape and size and with all materials. This is a good pattern for creating a little more interest in a floor. It is also possible to use tiles in a running bond in one room, then switch to a straight set in an adjoining room to get more interest and floor definition.

Herringbone Tile Floor

The herringbone pattern is made using rectangular tiles. The tiles are set at angles to one another, so it creates repeating “V” shapes in the floor. You can use any size or dimension of rectangular tile for this pattern. Long, thin tiles give you a different look than more proportional tiles. This is a good accent pattern. For example, you may want to create a tile “rug” in your foyer or bathroom with herringbone, with square tiles set around it.

Step Tile Floor Pattern

The step pattern is made using two sizes of square tiles. Use one tile in two sizes, use two tiles of the same material but different colors, or mix two different tile types. The small tile is set at the corner of the larger tile. This forces the next row over by the width of the small tile. In essence, it appears as though the smaller tile is stepping off the larger, which is how the pattern gets its name. This is a good pattern for any size or shape of room, but it works slightly better in long, thin rooms because it has an effect similar to the diagonal.

Cut Corner Floor Pattern

The cut corner pattern uses two different sizes of square tile. It can also use the same tile in two sizes, two colors of the same tile, or two different materials altogether. It is made by clipping at least one corner of each tile and installing the smaller tile in the gaps. You can clip one to four corners on each tile to create different degrees of interest from the added smaller tiles. This is a more traditional pattern that works best in formal areas like foyers.

Ashlar Floor Pattern

The Ashlar pattern is made by using three different tiles. It includes two square tiles and a rectangular tile. The tiles must be in relation to one another in size. The rectangular tile must be half the size of the larger square. The smaller square must be half the size of the rectangle. This creates a repeating pattern that moves at a diagonal across the floor. It has more interest and movement than many other patterns and works well in living rooms and kitchens.

Versaille Floor Pattern

The Versaille pattern is made up of four tiles. There are two squares and two rectangles. The smaller squares and rectangles are ¼ the size of the larger. This also creates a repeating pattern. It works best when you use large-format tiles, such as 24-inch squares, 8-inch squares, 24 x 36-inch rectangles, and 8 x 16-inch rectangles. Many tile sellers bundle their tiles in the Versaille pattern, so you need to round up your square feet to the nearest bundle.

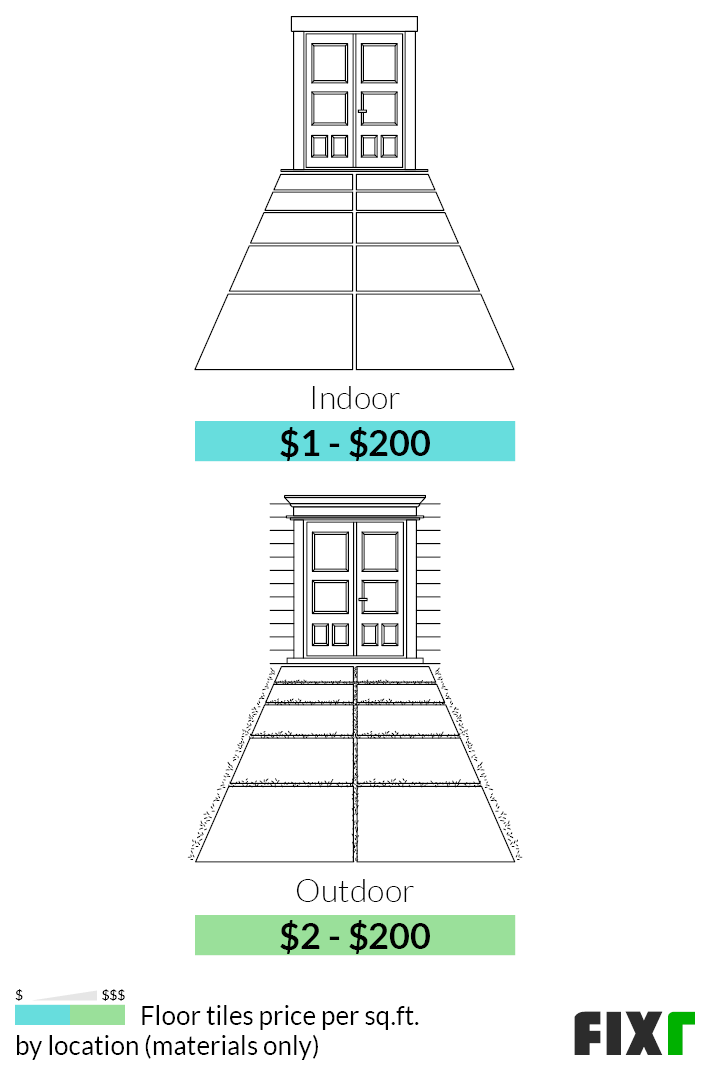

Floor Tiles Price by Location

Floor tiles can be installed in many areas, including indoors and outside. Any tile that is rated for outdoor use can be used indoors. However, not all tiles that can be used indoors can be used outside. It also varies by geographic location. For example, tiles that can be used in Florida or Arizona outdoors may not fare as well in New Hampshire or Wisconsin:

| Location | Average Costs per Square Foot |

| Indoor | $1 - $200 |

| Outdoor | $2 - $200 |

Indoor Floor Tiles

Tiles that can be used indoors have a cost range of $1 to $200 a square foot. Any tile can be used indoors. Even if a tile is specifically manufactured for outdoor use - thicker, for example - you can still use it inside without any consequence. Tiles used indoors tend to be thinner, ⅜-inch is the most common thickness for indoor tile, but ½-inch is also available. You can also use tiles indoors that absorb moisture or have bright colors that could potentially fade in direct sunlight. When choosing tiles for 3-season or 4-season rooms, some indoor tiles may not be appropriate, even though the room is technically indoors.

Outdoor Floor Tiles

Tiles that can be used outdoors costs between $2 and $200. Any stone tile will likely do well outdoors, although some hold up better than others long term. Porcelain tiles also do well outdoors because they are non-porous and not affected by freeze/thaw conditions. Ceramic tiles do well outdoors if they are ½-inch or thicker, are made with a vitreous clay body, or are used in warm climates. Glass tiles and thin, porous ceramic tiles do not do well in outdoor settings in general. If you choose a glazed tile, keep in mind that some bright colors fade outdoors.

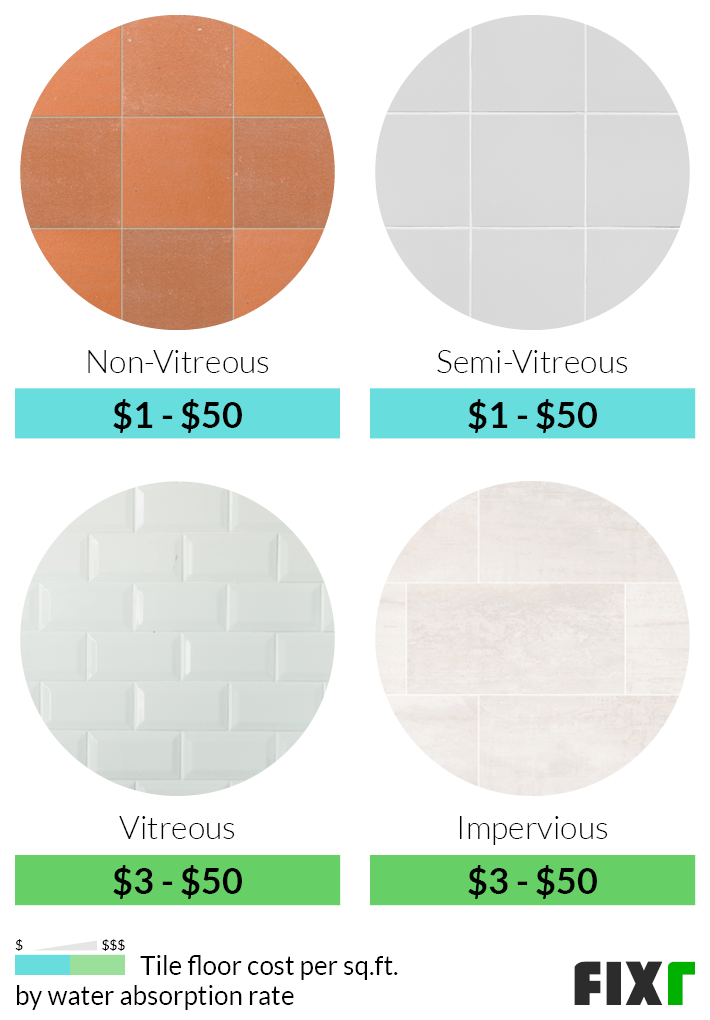

New Tile Floor Cost by Water Absorption Rate

Another important consideration in purchasing ceramic and porcelain tile is considering its water absorption (W.A.) rate. Expressed on the tile packaging as an umbrella shielding rain, the W.A. is calculated by determining the amount of water absorbed by a tile as a percentage of the tile’s weight. The denser a tile is, the less water it absorbs. Glass tile is non-porous and will not absorb water, while stone is rated in a completely different manner because all stone can absorb moisture:

| Type | Average Costs per Square Foot |

| Non-Vitreous | $1 - $50 |

| Semi-Vitreous | $1 - $50 |

| Vitreous | $3 - $50 |

| Impervious | $3 - $50 |

Non-Vitreous Tile

Non-vitreous tile ranges from $1 to $50 a square foot. It is very soft and usually monocottura, meaning it that has been fired once. Terra cotta is a good example of a non-vitreous type. It has a water absorption rate of 7%. The glaze on it helps keep moisture out, but since the glaze can crack or craze over time, it can absorb moisture. This can cause the clay body to stain. If you have a crazed glaze, it needs to be sealed to prevent staining.

Semi-Vitreous Tile

A semi-vitreous tile costs between $1 and $50 a square foot. This is a slightly denser typethat absorbs between 3% and 7% moisture. Most ceramic types are semi-vitreous. They may be monocottura or bicottura, meaning that they have been fired twice. If the glaze crackles, itthe tile needs to be sealed to prevent staining. Most semi-vitreous types are intended for wall use or light floor use only.

Vitreous Tile

Vitreous tiles average $3 to $50 a square foot. This type absorb only 3% moisture at most. Most porcelain and floor-rated ceramic ones are vitreous. They can be installed outdoors in warm climates. They may have a glaze with ceramic or be unglazed porcelain. They do not need to be sealed.

Impervious Tile

Impervious tiles cost between $3 and $50 a square foot. They absorb less than 0.5% of water. This means that they are considered frost-proof. Most impervious type is porcelain. It does not need to be sealed or require any special care. It can be installed anywhere, inside or out.

Labor Cost to Install a Tile Floor

The labor costs to install tile flooring varies, depending on the tile type, size, and location. The average range for installation costs are between $7 and $14 a square foot. The installation cost can be impacted by the material, tile size, and design complexity. Tiles ranging in size from 8” to 14” in size have the lowest costs, of around $7 to $9 a square foot for most materials.

Larger tiles, such as 18” or 24”, cost more to install because they require extra steps, such as backbuttering or putting additional mortar on the back of each tile. Costs for installation of large format tiles start at $10 to $12 a square foot.

Glass tiles and mosaic tiles tend to cost the most to install. Both require a mortar surface that is completely smooth with no key marks. Both often require additional mortar on the back of the tile and additional steps to secure the material. This is particularly true if the tiles are mounted onto the back of paper rather than onto mesh because the paper must be soaked off, changing the installation cost. Expect glass tiles and mosaic tiles to cost between $12 and $14 a square foot for labor.

For the installation of 200 sq.ft. of porcelain 12” tiles, expect labor to cost between $1,400 and $1,600 of the $3,500 total.

Cost per Sq.Ft. to Install Tile Flooring

The cost to install tile flooring ranges from $8 to $14 a square foot. However, elaborate patterns may raise this cost an additional 10% to 20%. This means that a big part of your installation’s costs are driven by the floor size.

| Floor Size | Room Dimensions | Average Cost Range (Labor and Material) |

| 50 sq.ft. | 10’ x 5’ | $450 - $10,700 |

| 100 sq.ft. | 10’ x 10’ | $900 - $21,400 |

| 144 sq.ft. | 12’ x 12’ | $1,296 - $30,815 |

| 200 sq.ft. | 10’ x 20’ | $1,800 - $42,800 |

| 500 sq.ft. | 20’ x 25’ | $4,500 - $107,000 |

| 1,000 sq.ft. | 20’ x 50’ | $9,000 - $214,000 |

Cost to Tile a Bathroom Floor

Bathrooms are one of the most common areas to install a tile floor. Bathrooms are wet areas, and this type o floor does a very good job of protecting the subfloor from moisture. Many types also offer a good slip-free flooring for safety. The average bathroom uses roughly 50 sq.ft. Depending on the type, this can mean a cost range of $450 to $10,700. Most people find that they pay between $450 and $700 for the average bathroom floor.

Cost to Tile a Kitchen Floor

Kitchens are another area where tile is very frequently installed. It holds up well to the high traffic of the kitchen, and it is easy to clean and take care of. The average kitchen is roughly 150 sq.ft. This means a total cost range of $1,350 to $32,100. However, most people choose them for the kitchen that fall between $1,350 and $3,000 for the flooring installed.

Cost to Replace a Tile Floor

If you have an existing tile floor and want to install something new, your total costs involve both the price to install the new floor and the costs to remove the old. These costs vary depending on your existing flooring. For example, some very old floors were installed with a “mud” job. This is a very thick layer of mortar that takes more time and effort to take up. Likewise, old vinyl floors are very expensive and time-consuming to remove. Some ceramic and stone floors come up very quickly and easily, however. Therefore, expect additional labor costs of between $1 and $5 a square foot. This makes your total cost range to replace the floor between $10 and $219 a square foot, depending on the type floor currently installed and the new one.

Measuring Tile Floors

Ideally, you should have your installer measure your floor for you before ordering the material. However, you can get a general idea of how much material you need by measuring the floor yourself. Start by breaking the room into sections where you can measure the length and width of each one. Take the measurements of each of these areas in inches. For example, if you have a room measuring 7-feet by 8.5-feet, you will use 84 inches by 102 inches. Multiply these two numbers together to get the square inches of the space. Add up all the square inches for the area you measured. Divide by 144 to get the total number of square feet for the area, then round up to the nearest whole number. Add 10% extra for cuts and waste. Add an additional 10% to 20% for complex patterns.

Keep in mind that most tile is sold by the box. You may need to round up to the nearest box size. Never round down. It is a good idea to have some material left over at the end of the job. This gives you material for repairs down the road.

Subfloor Requirements

Tile needs to be installed over a clean, level, and stable surface. It can be installed over concrete or plywood, although the most common underlayment is cement backer board. Your subfloor should be in good condition and able to hold the weight of the new floor. Sometimes if the floor is old or in poor condition, you may find after removing it that the subfloor needs to be replaced, which has an average cost of $1,500 to $1,650. If the subfloor is in good shape but moves slightly, your installer may screw it down more tightly or lay backer board over it, screwing it down tightly so that the floor does not move. Having a subfloor that is not level or moves can cause your new floor to crack over time.

While it is possible to tile over tile, this is not always recommended. Your new floor will only be as stable as the old floor. In addition, many old floors contain asbestos. Keying the mortar into the old floor may cause fibers to loosen. It is always a good idea to have the old floor removed first, before installing a new one.

Tile PEI Rating

PEI or Porcelain Enamel Institute Wear Rating is a measure of a tile’s resistance to abrasion. This measure reflects the suitability for floor traffic. The icon used to denote PEI is a bit drilling into a tile, which is found on the packaging. The chart below shows the difference between the PEI ratings. Only floors rated 3 and above are suitable for use on floors anywhere in the home. The ones rated 2 are suitable for use in very low traffic areas, such as powder rooms and shower floors.

| Rating | Description |

| PEI I | Lowest Resistance No foot traffic Not suitable for floors (walls only in residential/commercial applications) |

| PEI II | Low Resistance Light to no foot traffic Wall areas and floor areas with little to no foot traffic (residential bathrooms, shower floors) |

| PEI III | Light - Moderate Resistance Walls, floors, and countertops with normal foot traffic Tile for residential, not for commercial use |

| PEI IV | Moderate - Heavy Resistance Suitable for residential and light commercial uses |

| PEI V+ | Highest Resistance Suitable for all residential and commercial uses Heavy traffic |

Marble vs Porcelain Floor Tile

Marble and porcelain are both attractive and versatile materials for tile floors. Marble is a natural material made of metamorphosed calcite. It is quarried and cut into pieces of many different sizes. Porcelain is a manmade material created from compressed clay dust that is fired to very high temperatures.

Of the two, porcelain is more durable and lower maintenance. Marble is a natural stone, so it has more variation in color and pattern than porcelain, which is man-made. Marble needs to be sealed, both before grouting and regularly to prevent staining. Porcelain does not require sealing or other care to maintain its appearance. The two have comparable starting costs for material, although marble can become more expensive for some types. Marble may also have higher costs for installation due to the need for sealing and the need for a white latex additive thinset mortar for its installation. Porcelain is easier to install and more versatile in how and where it can be used.

Of the two, marble can be more expensive on average than porcelain. Below are the costs for installing 200 sq.ft. of each material.

| Material | Average Costs (Installed) |

| Porcelain | $2,000 - $4,400 |

| Marble | $3,000 - $5,000 |

Porcelain vs Ceramic Floor Tile

Both porcelain and ceramic are attractive, man-made tiles that can be used for flooring. Both materials are made from clay that is shaped and fired in a kiln. Ceramic tile is made of wet clay and has a glaze on its surface, while porcelain is made of compressed clay dust and may or may not be glazed. Because ceramic tile always has a glaze, it is more likely to scratch and chip. Porcelain is denser and harder, so it is less likely to chip. Its color also goes straight through the clay body, so marks are less likely to show.

Both materias come in a wide range of styles, sizes, and colors. Porcelain can better mimic the look of other materials like marble, while ceramic can be found in more vibrant colors, sizes, and shapes.

Porcelain’s starting costs are slightly more expensive than some types of ceramic, but handmade and specialty ceramic tiles are also available, which cost considerably more than porcelain. When comparing floor tiles, ceramic is usually the least expensive of the two options. Below are the costs for installing 200 sq.ft. of each material.

| Material | Average Costs (Installed) |

| Ceramic | $800 - $4,500 |

| Porcelain | $2,000 - $4,400 |

Tile Floor Maintenance

Your tile floor’s maintenance is directly impacted by the type of material you choose. Stone floors are higher maintenance than ceramic, porcelain, and glass. Stone requires regular sealing and pH neutral cleaners, while other materials can usually be washed with your preferred floor cleaner. In general, it should be swept regularly. If you choose to vacuum, do not use the beater brush option because it can scratch many floors. Mop as needed with the proper cleaner to remove surface dirt and stains.

Enhancement and Improvement Costs

Floating Tile Floor

Some flooring, including vinyl tiles and a few types of ceramic, can be floated. This means that they connect to each other, rather than to the substrate with mortar. The cost of these type of flooring ranges from $2 to $10 on average, and installation averages $4 to $7 a square foot. Floating floors are a good choice for encapsulating old asbestos floors or old vinyl floors that are hard to remove.

Frost Resistance

Frost-resistant tile is a product family that withstands freezing/cold winter weather without damage. It is also known as impervious tile and absorbs less than 0.5% of moisture. The packaging intended for exterior use indicates whether they are frost-resistant or not. If they are not frost-resistant, they can crack when exposed to freeze/thaw cycles. If they are frost-resistant, a snowflake appears on the packaging. They range in price from $3 to $50 per square foot.

Sealing

Not all tiles need to be sealed. However, all stone ones should be sealed with an impregnating sealer prior to grouting. Some textured ceramic and porcelain ones can benefit from sealing before grouting so that the sealer can act as a grout release, making clean up easier. If they need sealing, this is included in the cost of installation and is why stone ones typically cost more to install than ceramic and porcelain.

Wood-Look Tile Installation

Both ceramic and porcelain tiles can be found with a wood-look appearance. These are usually sold and installed in planks and have a very realistic color and texture, with the easy-to-care-for nature. They require grout and install like other types. They cost between $6 to $10 a square foot on average.

Additional Considerations and Costs

- Mosaic. When installing this type of flooring in a bathroom, consider installing mosaic tiles if you are concerned with slipping. The many grout lines around them increase the slip resistance.

- Planning. When ordering tile, purchase 10% to 15% more than needed to account for any mistakes, breakage, or future replacement that may be necessary.

- Large format. Large-format tiles can be installed in small rooms. Fewer grout lines make the floor look larger than it is, visually enlarging the room.

- Lincenses. In most U.S. states, flooring professionals need to be licensed.

- Estimates. Get quotes from a minimum of 3 professionals before hiring one to do the job. This ensures you are not paying for more than the job is worth.

- Scheduling. Ask about a timeline before the job is started so that you can plan around your schedule.

- Saving tips. Save money by purchasing the tile and other materials yourself, rather than getting charged extra by the installer.

- DIY. Before beginning the tiling process, remove tiles from different boxes and mix them to ensure that the color differences do not form a pattern in your floor.

- Installation. Start laying tile in the center of the wall farthest from the door you enter from and then work out toward the sides from that point.

FAQs

- How do you tile a bathroom floor?

The process varies by room and tile, but in general, you will start at the center of the wall farthest from where you enter the room. Apply a thin layer of mortar to the floor, and key it with the grooves of the trowel until it is all the same depth. Press them into the mortar and move outward. Wait 24 hours, then grout them. Wait an additional 24 hours before walking on the floor.

- Where do you start laying floor tiles?

It is best to start in the center of the wall farthest from the door you enter from. Move out evenly to each side from there.

- How do you lay out a tile floor?

The tiles can be dry laid before installation, starting at the center of the wall farthest from the door and moving out evenly. Once you are satisfied with the cuts and pattern, they are installed in the same manner, with a thinset mortar being spread on the floor first. It is grouted about 24 hours later.

- How much does it cost to tile a 12 x 12-foot room?

This depends mostly on the type of tile you are installing. It costs between $1 and $200 a square foot, and installation costs between $8 and $14 a square foot on average. This totals $9 to $214 a square foot, so for 144 square feet, this is $1,296 to $30,186.

- How much does it cost to tile 1,000 square feet?

This depends mostly on the type of tile. It costs between $1 and $200 a square foot, with installation costing between $8 and $14 a square foot on average. This makes the total cost range for 1,000 sq.ft. between $9,000 and $214,000.

- Which tiles are best for flooring?

The best tiles are those that are rated for commercial floor use or heavy residential floor use. This means a grade of either 4 or 5. Avoid anything less than a 3 because they will wear too quickly.

- Which is better, glossy or matte floor tiles?

Neither option is better than the other. This is entirely a personal preference. It also depends slightly on the material. Glossy ceramic tiles do not wear as well as glossy porcelain ones. However, glossy marble ones offer better slip resistance than matte porcelain ones.

References

- Build Direct. “What Are the Best Outdoor Tile Options for a Deck or Patio?"

https://www.builddirect.com/blog/what-are-the-best-tile-options-for-your-deck-or-patio/ - Craftsman Book Company. National Home Improvement Estimator, Ed. by Ray F. Hicks (Carlsbad, CA, 2021).

- Craftsman Book Company. National Renovation & Insurance Repair Estimator, Ed. by Jonathan Russell (Carlsbad, CA, 2021).

- Craftsman Book Company. National Repair & Remodeling Estimator, Ed. by Joshua Paxton (Carlsbad, CA, 2021).

- FIXR Cost Guides and Cost Database.

- HGTV. “All About Tile Flooring: Choosing the Best Type."

https://www.hgtv.com/design/decorating/design-101/all-about-tile-flooring-choosing-the-best-type-pictures - The Home Depot. “Tile."

https://www.homedepot.com/b/Flooring-Tile/N-5yc1vZar0y - The Home Depot. “Types of Tiles."

https://www.homedepot.com/c/ab/types-of-tiles/9ba683603be9fa5395fab907226ad93 - The Spruce. “Ceramic Tile Flooring Review: Pros and Cons."

https://www.thespruce.com/ceramic-flooring-pros-and-cons-1314687 - The Tile Shop. “How to Lay Tile.”

https://www.tileshop.com/resources/how-to-lay-tile